Heated Filtered Bath

Heated Filtered Bath

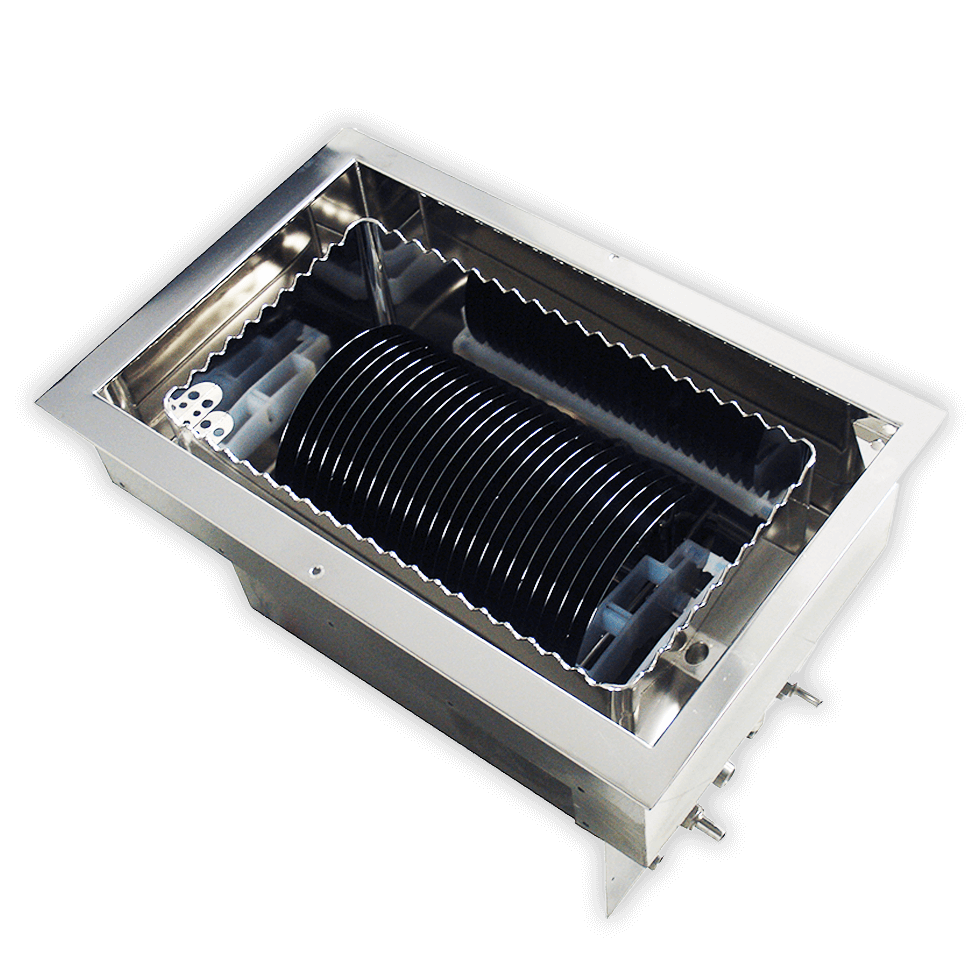

JST’s Heated Filtered Bath improves chemical life and efficient particulate removal by continuously filtering the process chemicals.

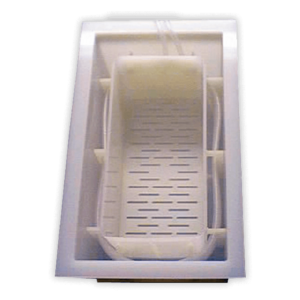

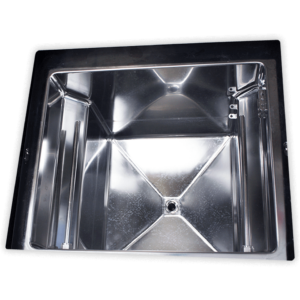

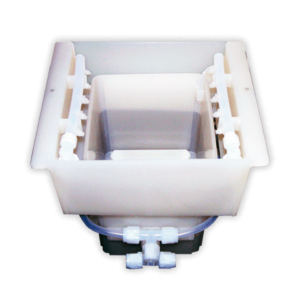

- Material Options: natural polypropylene, PVDF, PFA, quartz, or 316L stainless steel

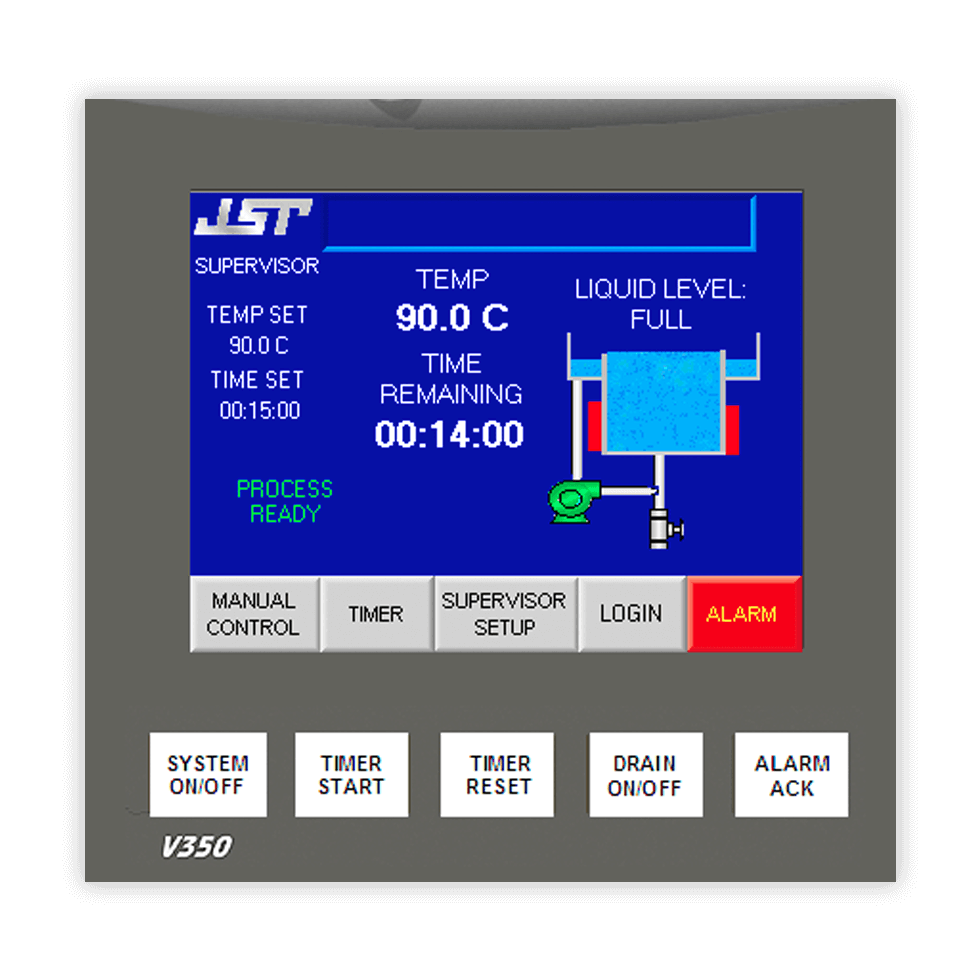

- PLC controlled with color touchscreen

- Programmable temperature, recirculation flow rate, and process time

- Full liquid level detection

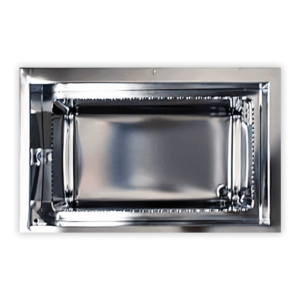

- Sloped bottom to drain

- Temperature range 40º C- 180º C /- 1º

- Thermocouple, Type J temperature probe

- Standard 10″ inline filter housing

- Coved corners to eliminate particle traps

- 4-sided serrated overflow weir

- Drain screens

- Pneumatic bellows recirculation pump

- Air operated valves

- Dispersion wafer cassette platform

- Customizable to fit product

- Ultrasonic Agitation

- Condensing cooling coils

- Mechanical agitation

- Automated or manual lid

- Dedicated drain to carboy

- Flow sensor

- Electric centrifugal pump

- Pump stroke monitoring

- Auto chemical fill and blending

- DIW drip to maintain chemical concentration

- Installation into JST’s Manual Wet Benches or Automated Wet Benches

- Customizable product racks, fixtures, or wafer cassettes

- Piranha / Sulfuric Peroxide Resist Stripping

- Solvent Photoresist Stripping

- Nitride Etch

- Metal Etch

- KOH Etch / TMAH Silicon Etching

- Mixed acid etch

- SC1 Clean

- SC2 Clean

Heated Filtered Bath Overview

JST’s Heated Filtered Bath improves chemical life and provides efficient particulate removal by continuously filtering the process chemicals. The chemical enters the bath from the bottom, flows uniformly across the substrates, and then cascades over a four-sided serrated weir. The heating elements are bonded to the outer walls, insulated, and contained within an outer shroud that is N2 purged. Inline heaters are available for large, high temperature baths that require a fast heat-up time or higher processing temperatures.

As with all JST process modules, the heated baths comes with JST’s standard 24/7 Technical Support.

Related Products