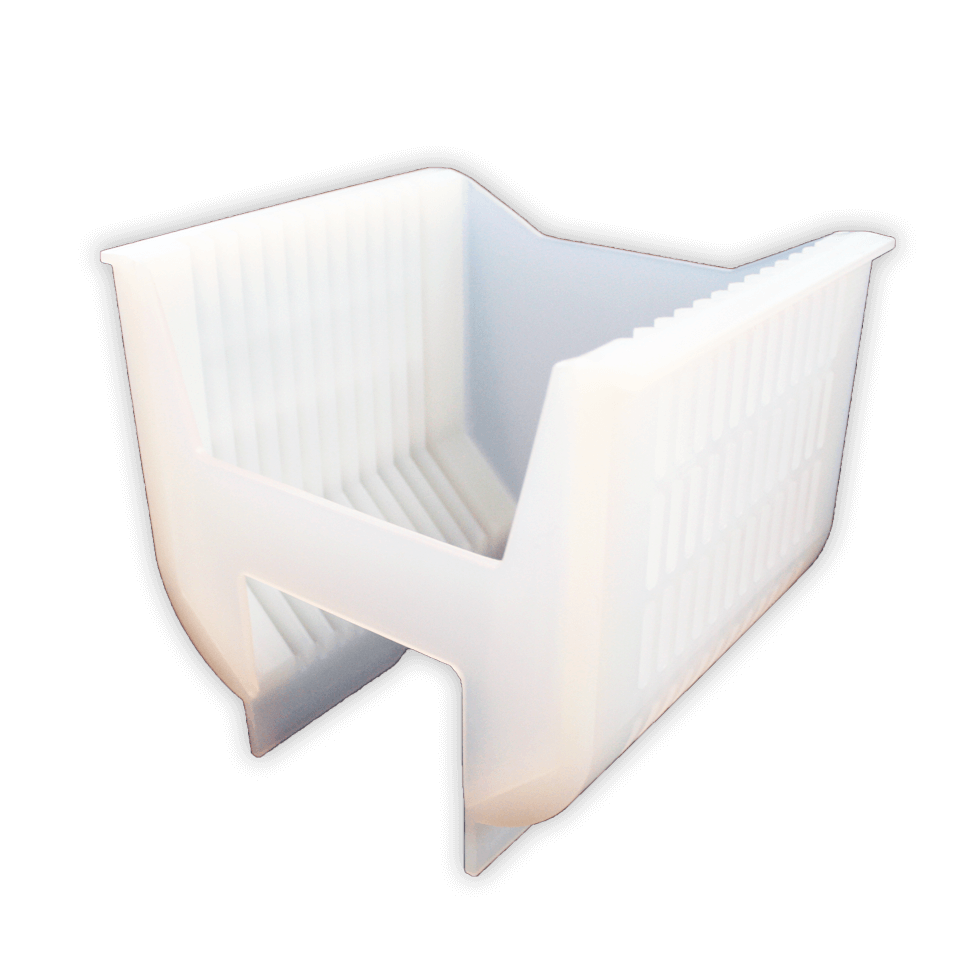

Wafer Cassettes

Wafer Cassettes

JST’s customizable Wafer Cassettes are built to enhance specialized applications when standard off-the-shelf cassettes are unavailable.

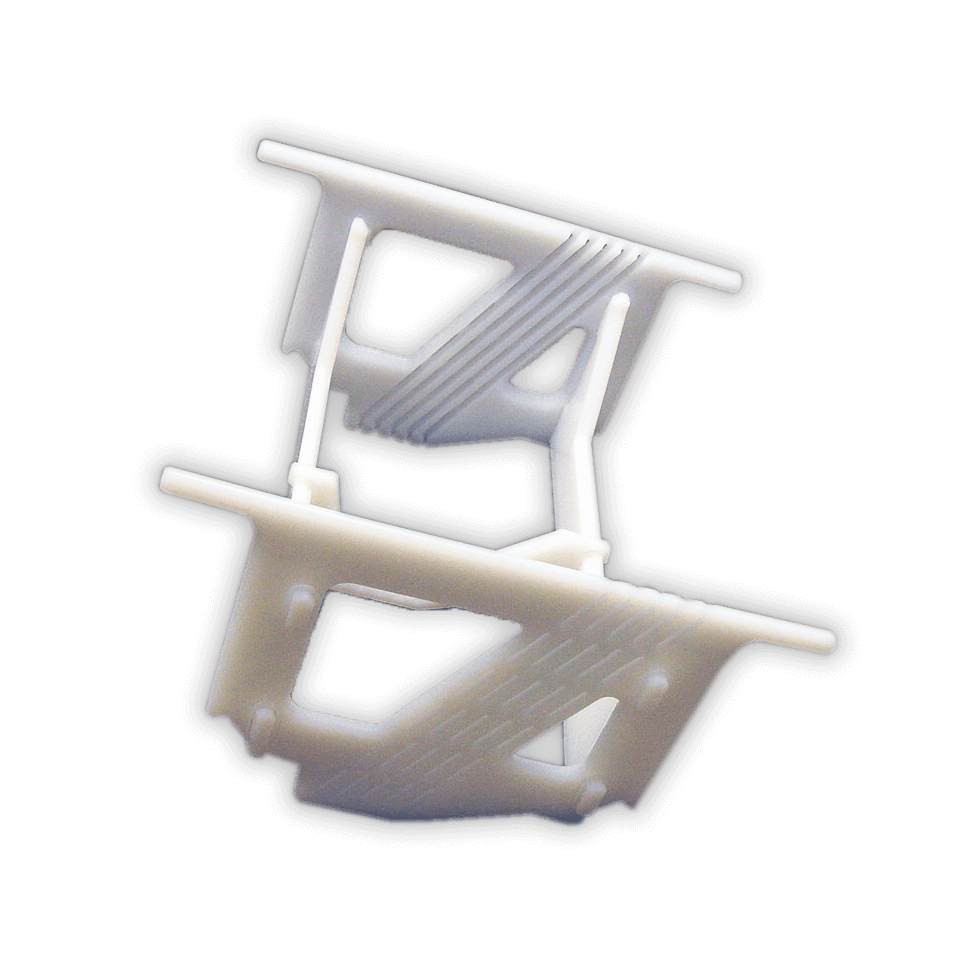

- Material Options: PFA Teflon, PTFE Teflon, ECTFE Halar, PVDF, 304L stainless steel, 316 stainless steel, or natural polypropylene

- Customizable sizes and shapes

- Substrate spacing/pitch

- Substrate contact points

- Side opening profiles

- Substrate orientation

- Mixed substrate sizes

- Equipment automation features

- Cassette handling features

- Detachable handles

- Metal Lift Off

- Electroless Plating

- Uniform etching

- Minimize first wafer effects

- Improved DIW rinsing

- Improved drying

- Wide slot for warped substrates

- Custom equipment automation

Wafer Cassettes Overview

JST’s customizable semiconductor process Wafer Cassettes can be developed to increase chemical flow-through dynamics through various optional features to increase chemical flow-through dynamics in the cassettes while reducing liquid and material trap points.

Our in-house design team collaborates with all customers to design and manufacture specialized process cassettes at the lowest possible cost. With JST’s customizable manufacturing capabilities, we can accommodate the production of cassettes in various sizes, shapes, substrate pitches, spacing, and orientations. The tooling, prototype, and minimum order costs associated with mold manufacturing do not apply when ordering process cassettes with JST.

As with all JST Cleanroom Furniture & Accessories, Wafer Cassettes come with JST’s standard 24/7 Technical Support.

Related Products