About JST

Semiconductor Equipment Manufacturers

JST defines the standard for safety, reliability, and performance in wafer surface preparation among semiconductor equipment manufacturers—with 24/7 customer support and an unwavering commitment to absolute quality.

ft² Facility

Years in Business

Customer Support

%

Regulatory Compliant

Semiconductor equipment manufacturers with expertise in designing, building, and servicing wet benches and chemical processing systems

For the past 40 years, JST has been designing and building innovative and efficient wet benches and semiconductor processing equipment for cleanroom applications. The company owes its venerability to continuous innovation and reinvention — redefining the standard of safety, reliability, and performance in the surface preparation market.

Although it didn’t invent the wet bench, the company is laser-focused on continuing to improve upon it. By optimizing the “tried and true” methods of semiconductor surface preparation, JST creates more efficient manufacturing practices — transforming the chemical processes that are integral to our semiconductor equipment manufacturers’ workflows and making them smaller, faster, and more cost-effective.

-

Cleaning Applications

Based just outside Boise, ID, JST’s modern-day facility is outfitted with the latest state-of-the-art technology. The production team comprises highly-skilled tradesmen, manufacturers, and expert engineers relentlessly committed to building superior products and creating a customer experience that exceeds expectations.

The company’s 60,000 sq. ft facility enables a vertically-integrated production model, a one-stop solution for wet bench manufacturing. JST offers precision cleaning, wet processing, and drying equipment for applications in semiconductors, electronics, medical, optics, and other industries that require cleanliness in their production process.

When it comes to batch processing, single-wafer processing, cost-efficient automation, reduced chemical usage, or supporting customer transitions to larger wafer sizes, JST’s production capabilities are versatile, and the company’s 24/7 lifetime technical support is unmatched.

Mission & Values

To provide innovative wet process and automation solutions that are engineered and manufactured to be cost effective, safe, and of the highest quality.

Innovation

JST’s products transform the surface preparation processes by optimizing the cleanroom footprint space and designing more efficient and productive equipment.

Respect

We recognize the importance and humanity of others, treating everyone with courtesy, politeness, and kindness. We show up with a positive attitude.

Good Judgement

When making decisions, we think critically and act thoughtfully. We are always ethical and draw upon empathy when differing values collide.

Teamwork

With a clear understanding of clients’ processes and needs, JST collaborates with end users to customize cost-effective, functional, and safe solutions.

Integrity

We are honest and ethical in our actions, seeking results in the best interests of our team members and clients. We honor our commitments.

Communication

Open and direct communication allows for seamless collaboration. We listen with intent, speak honestly, and ensure every voice is heard.

Fast Facts

Company Highlights

Resources

JST News & Announcements

Articles, company announcements, product updates, and information about the semiconductor wet processing manufacturing industry.

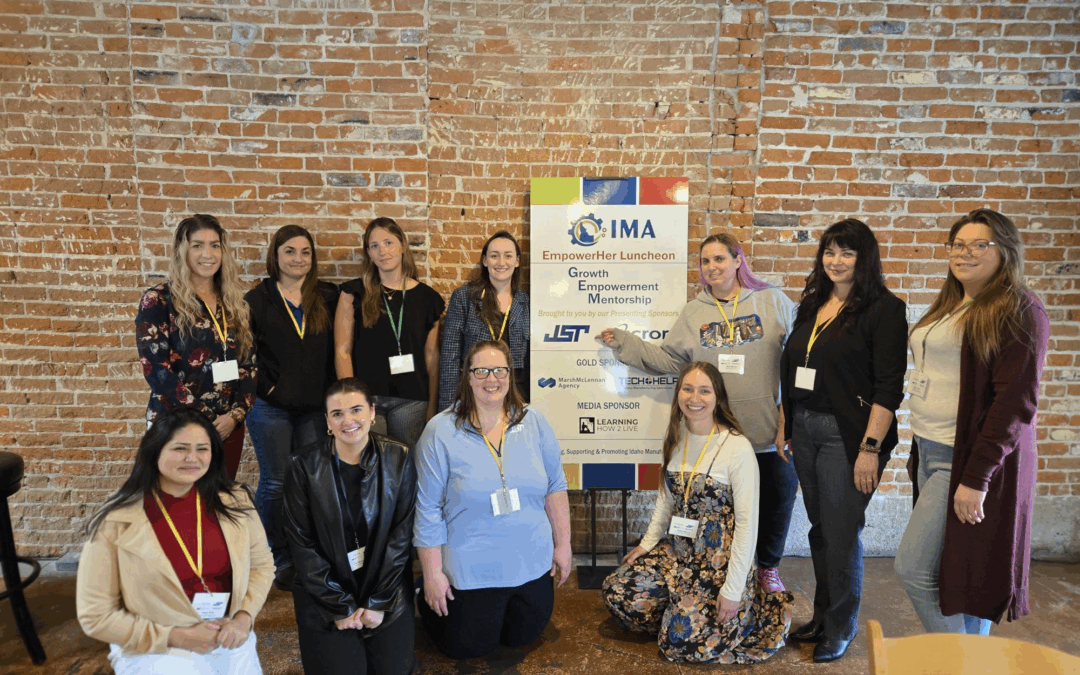

How to Attract and Retain More Women in STEM Fields

The fabs, facilities, and semiconductor manufacturing industry driving the world’s greatest technological innovations face a dire issue of closing...

Our Top 3 Secrets for Attracting and Retaining Skilled Manufacturing Talent

Mega tech companies like Taiwan Semiconductor Manufacturing Company (TSMC) and Apple are expanding with new facilities and fabs investments on U.S....

JST Names Dr. Ismail Kashkoush as Chief Technology Officer

Dr. Ismail Kashkoush, technology leader in process engineering, to lead JST’s next chapter in product development as Chief Technology Officer.

HBr Etching Enables Strong Demand in Optoelectronics and Fiberoptics Markets

Learn about the benefits of HBr wet etching for optoelectronics, including improved uniformity, repeatability, and cost of ownership.

Subscribe

Get the latest news & updates

Sign up to receive occasional email updates about new products, announcements, exclusive promotions, and more. We will never spam your inbox or share your personal information with anyone else.