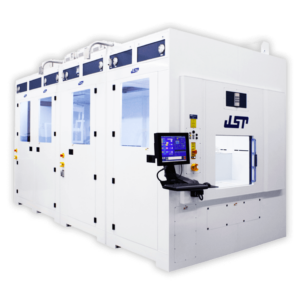

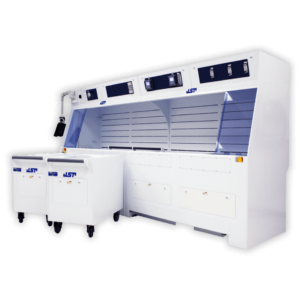

EPI Foreline Tube Cleaner

EPI Foreline Tube Cleaner

JST’s EPI Semiconductor Foreline Tube Cleaner provides manual or semi-automated parts cleaning for tubes and vacuum components in an exhausted dual-contained wet bench.

- Material Options: FM-approved PVC-C or white polypropylene

- Internal stainless steel frames isolated from process chemistry

- Designed with a programmable logic controller (PLC) in addition to an industrial PC that control the entire wet bench

- Ergonomically designed front load/unload access for product utilizing an automated vertical lift

- Semi-automated operation platform

- Front removable panels for easy maintenance access

- Recessed bath design pulls chemical fumes through the exhausted dual containment plenum

- Automated chemical handling using an on-board chemical storage reservoir

- Integrated re-circulation and filtration of process chemistries

- Motorized assist product lifts

- Rear access maintenance area provides dual containment for reservoirs, pumps, filters, and plumbing

- Custom part fixtures

- Additional on-board chemical storage reservoirs

- External Chemical Dispense Cart fill and Chemical Waste Pump Cart

- Bulk chemical fill interface

- On-board chemical analyzer with integrated concentration control and monitoring for reduced chemical usage

- Hot DIW rinse

- Temperature controlled heating of process chemistries

- GEM/SECSII factory automation interface

- Ergonomically mounted 23″ color touchscreen monitor with JST’s GENII Software

- Local data logging of all process parameters and lot tracking stored on the PC’s hard drive

- Nitrogen and DI water hand spray guns

- Additional facility drain options

- SEMI S2 Certification

- CE marking

- 3rd party electrical inspections

EPI Foreline Tube Cleaner Overview

JST’s Foreline Tube Cleaner wet bench is designed to create a safe and efficient method for cleaning foreline tubes, vacuum components, and other parts of an EPI reaction chamber. The exhausted wet bench is compatible to use with acids, bases, oxidizers, or other cleaning chemistries associated with the foreline maintenance process.

The integral automated lift provides safe ergonomic cleaning of large heavy components. This wet bench is designed with front/unload access for product that requires an automated vertical lift. Equipped with an on-board chemical storage reservoir, the tube cleaner is equipped with automated chemical handling abilities.

JST’s cleaner provides manual or semi-automated parts cleaning for tubes and vacuum components in an exhausted dual contained wet bench.

As with all JST wet benches, this product is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products