Metal Lift Off

Metal Lift Off

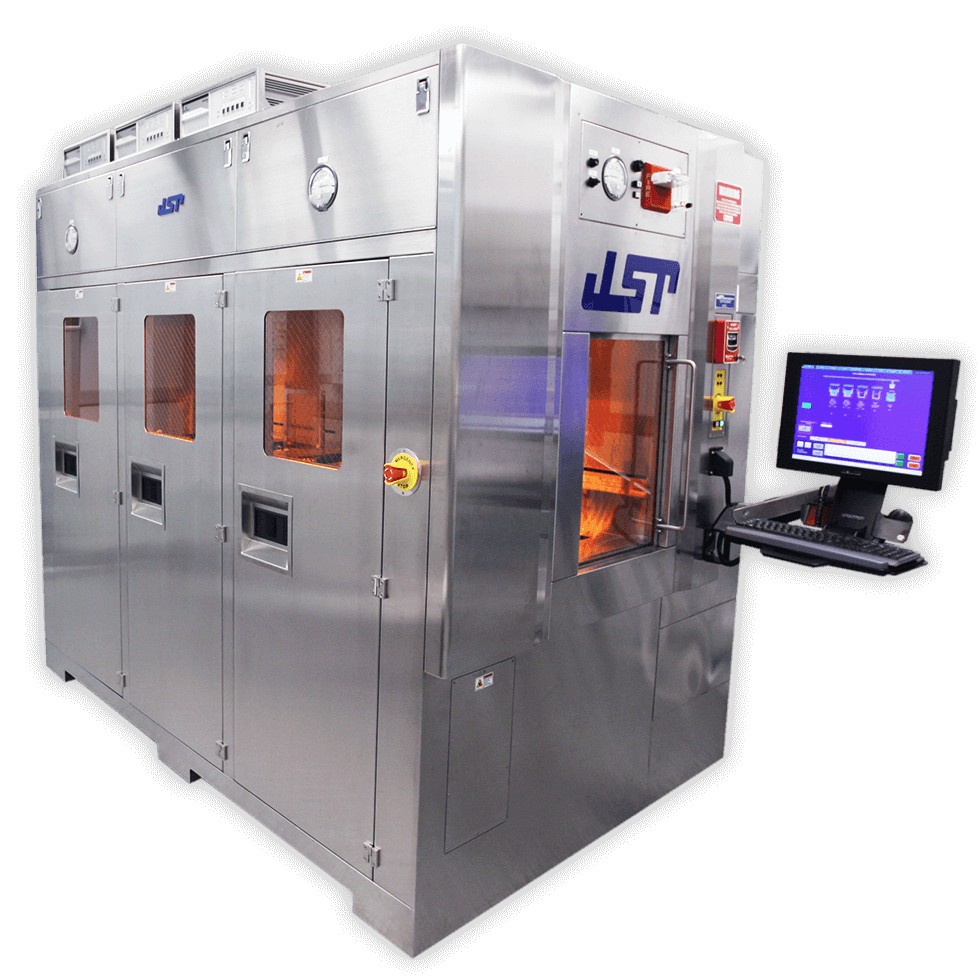

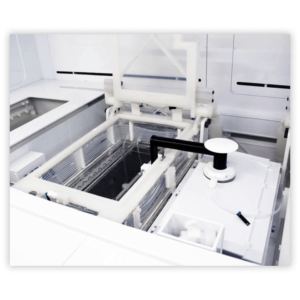

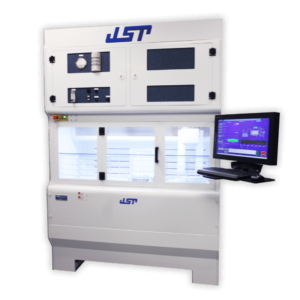

JST’s Metal Lift Off process retains removed layers of metal and the resist—preventing it from re-depositing on the wafers. Using a heated downflow bath, substrates are directed down and away from the product.

- STEP 1: NMP Dirty – Heated Downflow Bath

- STEP 2: NMP Clean – Heated Downflow Bath

- STEP 3: Acetone – Ambient Static Bath

- STEP 4: IPA – Ambient Static Bath

- STEP 5: Dry – Closed Loop Vapor IPA Dryer

OR

- STEP 1: DMSO Dirty – Heated Downflow Bath

- STEP 2: DMSO Clean – Heated Downflow Bath

- STEP 3: Rinse – Quick Dump Rinser Bath

- STEP 4: Dry – Surface Tension Gradient Dryer (Marangoni Dryer)

Metal Lift Off Overview

The Metal Lift Off process provides an alternative to etching. Many semiconductor devices, particularly those made with gallium arsenide (GaAs) or indium phosphide (InP), require the removal of metal layers by etching. However, materials such as gold are difficult and expensive to remove by etching due to their inertness. Chemical lift off is a method of patterning a target material (typically a metal lift off) using a sacrificial layer (typically photoresist) to define the pattern. First, the sacrificial layer is applied and patterned; then, the target material is deposited on top. The problem is keeping the removed metal layer and the resist from re-depositing on the wafers. JST accomplishes this task by using a Heated Downflow Bath where metal and resist are directed down and away from the product. Inline filters in the drain plumbing capture the metal, preventing re-deposition back on the substrate. The filters can be cleaned as part of a periodic maintenance routine, and costly metal can actually be recovered.

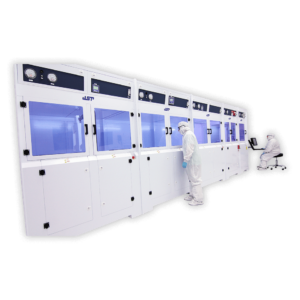

JST’s Class 10 Applications Lab enables our customers to develop processes using real-world tools, process modules, and chemicals. This, coupled with our partnerships with various chemical vendors, allows JST to collaborate and develop cleaning solutions for our customers.

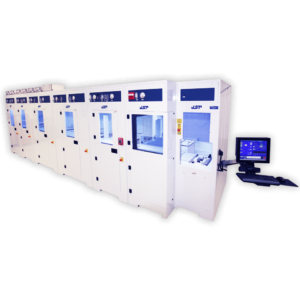

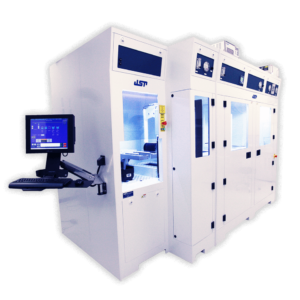

All of JST’s wet benches and lab furniture are designed with safety, reliability, and productivity in mind. Our wet lab equipment features a modular design that meets all Semi, CE, NFPA, and OSHA requirements. All cleanroom furniture is designed for safe, convenient, and efficient performance in cleanroom environments Our expertise as semiconductor equipment manufacturers includes onsite plastics and contract metal fabrication as well as mechanical and electrical assembly. As with all JST wet benches, our Metal Lift Off is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products