Industrial Ultrasonic Cleaner

Industrial Ultrasonic Cleaner

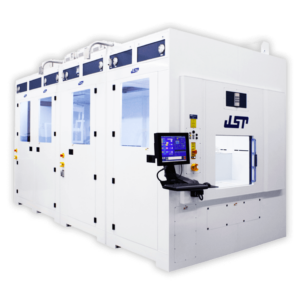

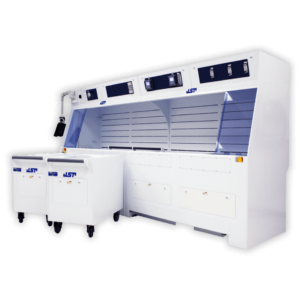

JST’s Industrial Ultrasonic Cleaner is a self-contained wet bench designed to deliver precision cleaning of semiconductor parts using ultrasonic bath agitation.

- Material Options: 304L stainless steel with 316L stainless steel process bath and wetted parts

- Ultrasonic bath agitation with a variety of single frequencies (40, 72, 104 kHZ)

- Designed with a programmable logic controller (PLC) in addition to a color touchscreen that control the entire wet bench

- Removable panels on the front, side, or rear of the parts cleaner for easy maintenance access

- Designed with a programmable logic controller (PLC) in addition to a color touchscreen that controls the entire wet bench

- Purged electrical compartments

- Explosion-proof rated components in cleaning process area

- Available with and without exhaust

- Exhaust failure alarm

- Welded sealed secondary containment

- Seismic anchors

- Multiple ultrasonic frequencies: 40 kHz, 80 kHz, 120, 140, 170, 220, or 270 kHz

- Integrated re-circulation and filtration of process chemistries

- DI water cascade rinsing

- Hot DI water

- Nitrogen blow-off or IPA Vapor Drying

- External Chemical Dispense Cart fill and Chemical Waste Pump Cart

- Bulk chemical fill interface

- Customized bath sizes

- Integrated reservoirs for storage and reuse of cleaning solutions

- CO2 fire suppression

- Automatic lid

- SEMI S2 certification

- CE marking

Industrial Ultrasonic Cleaner Overview

JST’s Industrial Ultrasonic Cleaner wet bench is a self-contained, automated compact unit designed for critical cleaning of semiconductor parts. JST’s ultrasonic cleaners are designed for precision parts cleaning using ultrasonic agitation. These versatile cleaners can be configured for use with flammable solvents and aqueous chemistries.

This self-contained wet bench performs precision cleaning of parts by using ultrasonic agitation. The Industrial Ultrasonic Cleaner provides a variety of single frequencies, including 40, 72, and 104 kHz. This cleaner may be customized to feature additional ultrasonic frequency options beyond those of JST’s standard model. These optional frequencies include 80, 120, 140, 170, 220, or 270 kHz.

JST’s industrial cleaning process performs multiple capabilities, including heating, over-flow re-circulation, multiple chemistries, DIW rinsing, and drying. As an optional feature, JST customers may choose to add integrated re-circulation and filtration of process chemistries to their cleaner system. Nitrogen blow-off or IPA Vapor Drying are also available.

As with all JST wet benches, this product is designed for ease of maintenance activities and come with our standard 24/7 Technical Support.

Related Products