Process control in semiconductor manufacturing is no longer a “nice to have” capability – it is now a must-have. Across MEMS, power devices, optoelectronics, advanced packaging, and mainstream IC manufacturing, chipmakers are under constant pressure to improve yield, reduce cost of ownership (CoO), and accelerate time to market. To do this, they need tighter, more intelligent control of their processes.

One major driver is visibility into resources and performance. Fabs increasingly want to know—in real time—the quantities of chemicals, water, air, and energy tools are consuming, and how those variables correlate to results. At the same time, shrinking geometries, new device structures, and broader material diversity are raising the bar for control. You want sensors and software that don’t merely monitor and report but keep the process inside tight control bands—and you’re increasingly asking us for this closed-loop capability.

Just as important, process control has a very practical financial impact. Better control can mean better yield and less scrap, but it can also help delay or reduce capital spending. If you can run more stable processes, you can often invest less in additional capital equipment—or spread that investment over more time—while still meeting production and quality goals.

Where Variability Shows Up In Wet Processing

Wet processing is full of interacting variables, and the hard part is that small drift can have outsized effects. Chemistry concentration and temperature are obvious challenges, but flow rates, pressure monitoring, acoustic energy (megasonic/ultrasonic), and even how water is injected—rate, mechanism, and repeatability—can change outcomes. Whether the process is batch-to-batch or wafer-to-wafer, customers need uniformity and repeatability they can trust.

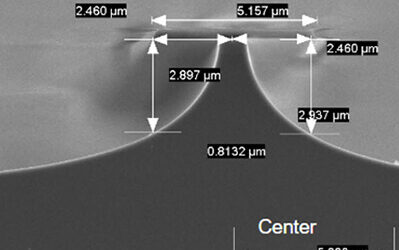

The defects you care about most often come down to contamination and surface integrity. In the front end, we’re talking about particulates and ionic contamination (elemental contaminants), plus the need to remove unwanted films like native oxide. In the back end, it’s often polymer residue, corrosion risk with metalized layers, and keeping surface roughness within acceptable limits—especially when chemistries are etching and can change surface texture. Gate oxide integrity and voltage-to-breakdown performance can also be impacted when cleanliness and control aren’t tight enough.

Mixed materials and applications complicate this further. The underlying requirements don’t really go away—cleanliness, repeatability, uniformity—but thresholds shift depending on the technology node and device sensitivity. A leading-edge logic fab may measure contamination at far smaller particle sizes than a compound semiconductor line, yet the process-control discipline required is just as real.

Then there’s data. To achieve stable, high-yield processes, fabs need traceability and fast troubleshooting. We’re tracking a tremendous amount of information—down to every minuscule movement of robots and every parameter in chambers, tanks, and exhaust. The challenge is storing it, making it usable, and setting the foundation for more advanced analytics over time.

How JST Is Raising The Bar

At JST, we view process control as a system-level approach that starts with tool design and extends through sensors, software, recipe strategy, and long-term support. We are installing sensors in our wet processing systems to track chemical concentration, temperature, pressure, flow, exhaust behavior, and even real-time energy consumption. We’re also building a tool-level cost-of-ownership model that uses historical performance to establish expectations and help identify inefficiencies and opportunities to optimize.

The Best Known Method Process Guide

A cornerstone of our approach is our Best Known Method (BKM) process guide. Wet tools can involve thousands of variables, and you shouldn’t have to start from a blank page every time you install a tool or onboard a new engineer. Our BKM gives you a day-one starting point: the tool runs under defined conditions, with expected outcomes, so both their team and ours have a baseline for ramp, troubleshooting, and long-term stability. And when performance changes months later, as fab conditions evolve, today’s settings can be compared to the baseline to identify what shifted, allowing you to quickly determine adjustment options.

Prioritizing Adaptability and Flexibility

We also differentiate through flexibility and efficiency. We design hardware and software so we can adapt to specific customer needs, and we take pride in building tools with a smaller footprint—often translating into reduced exhaust needs and lower volumes of chemicals and water. Those factors directly support lower CoO, without sacrificing performance.

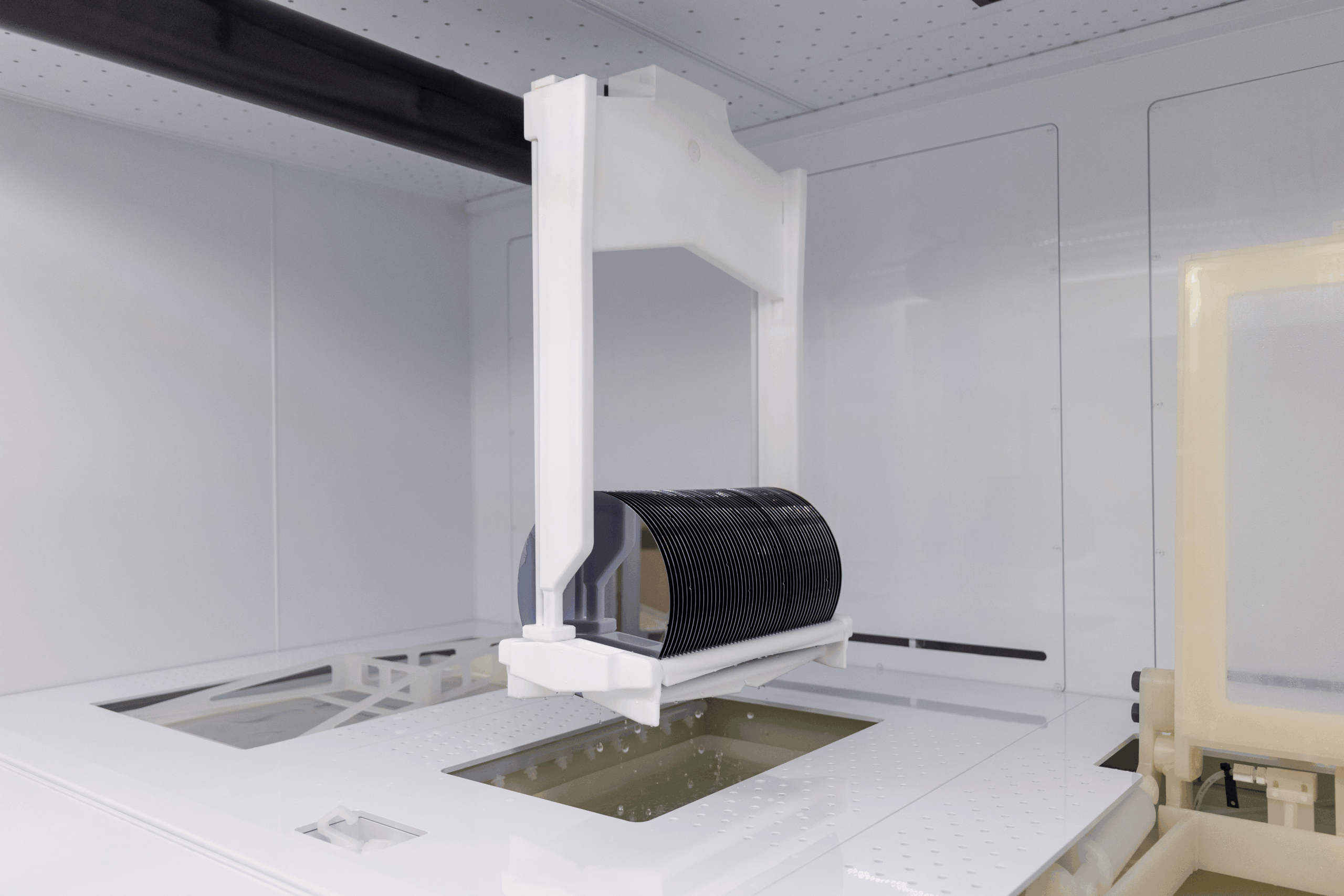

Finally, we focus on key wet processing details: how wafers are held, how they’re dried, how particles are removed, and how critical rates and conditions are stabilized. A good example is our Apex dryer. By designing a fixture that can accommodate a wide range of wafer thicknesses, we helped a customer achieve strong results with one dryer instead of multiple units—significantly reducing tool count, cost, and process complexity.

To discuss your process-control challenges and goals, reach out to JST at info@jstmfg.com. We’ll show you how our tool architecture, sensing strategy, and BKM process guide can help you ramp faster, run more repeatably, and get more value from every wet step.