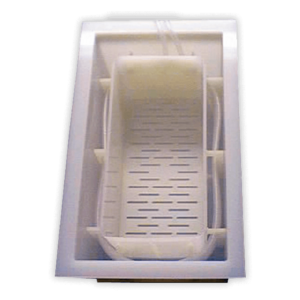

Heated Downflow Bath

Heated Downflow Bath

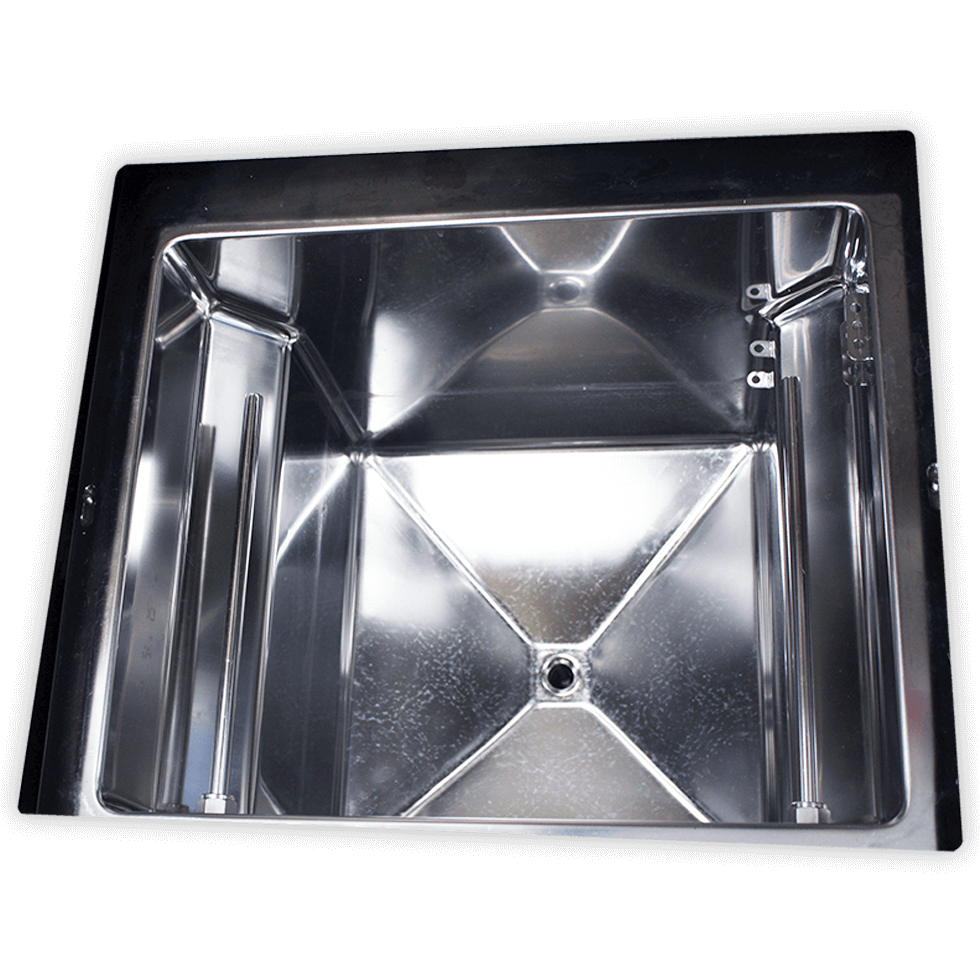

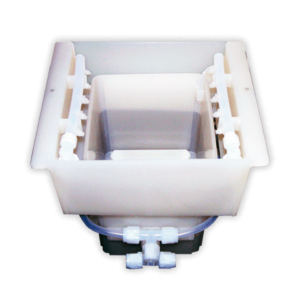

- Material Options: 316L stainless steel brushed or electropolished finish

- PLC controlled with color touchscreen

- Programmable temperature, recirculation flow rate, and process time

- Full liquid level detection

- Sloped funneled bottom to drain

- Adjustable top chemical inlet sparger bars

- Explosion-proof solvent inline heater

- Temperature range: 40º C- 120º C /- 1º

- Thermocouple Type J Temperature probe

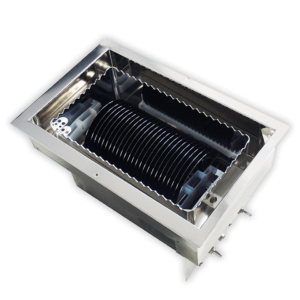

- Pneumatic bellows recirculation pump

- Standard 10″ inline filter housing

- Inline strainer for metal or material reclaim

- Stainless steel air operated valves

- Coved corners to eliminate particle traps

- Customizable to fit product

- Ultrasonic agitation

- Condensing cooling coils

- Mechanical agitation

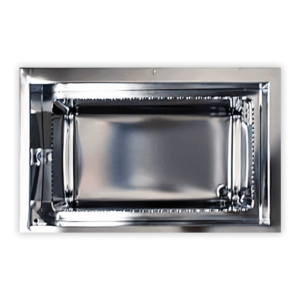

- Automated or manual lid

- Dedicated drain to carboy

- Flow sensor

- Electric centrifugal pump

- Pump stroke monitoring

- Auto chemical fill and blending

- Installation into JST’s Manual Wet Benches or Automated Wet Benches

- Customizable product racks, fixtures, or carriers

- Metal Lift Off

- Thick Film or Dielectric Removal

- Photoresist Stripping

Heated Downflow Bath Overview

JST’s Heated Downflow Baths are designed for efficient metal lift off and removal of thick films. Recirculation and filtration are provided to remove the lifted material from the bath and chemistry.

Filtered, heated, solvent chemistry flows into the top of the bath, directly over the substrate lifting off the materials and removing them out the drain. This downflow action eliminates the possibility of the removed materials returning to the wafer.

JST’s downflow design captures the lifted-off materials in an external strainer for reclaim, and the chemistry is continuously filtered. This cost-saving system prolongs chemical life. For fast heat up and high temperature control, an inline heater is provided.

As with all JST process modules, heated baths comes with standard 24/7 Technical Support.

Related Products