Heated Static Bath

Heated Static Bath

JST’s Heated Static Baths are designed to safely maintain a consistent temperature for acids, bases, or solvents processing.

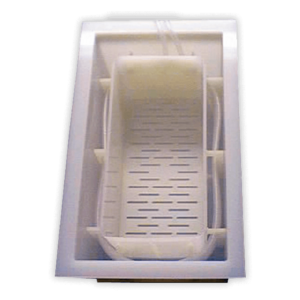

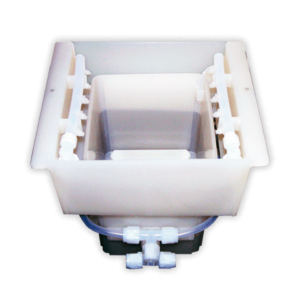

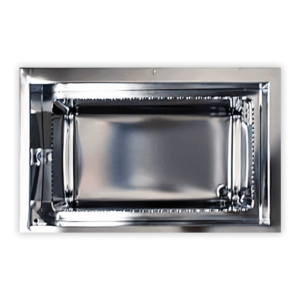

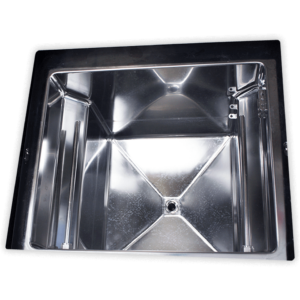

- Material Options: natural polypropylene, PVDF, PFA, quartz, or 316L stainless steel

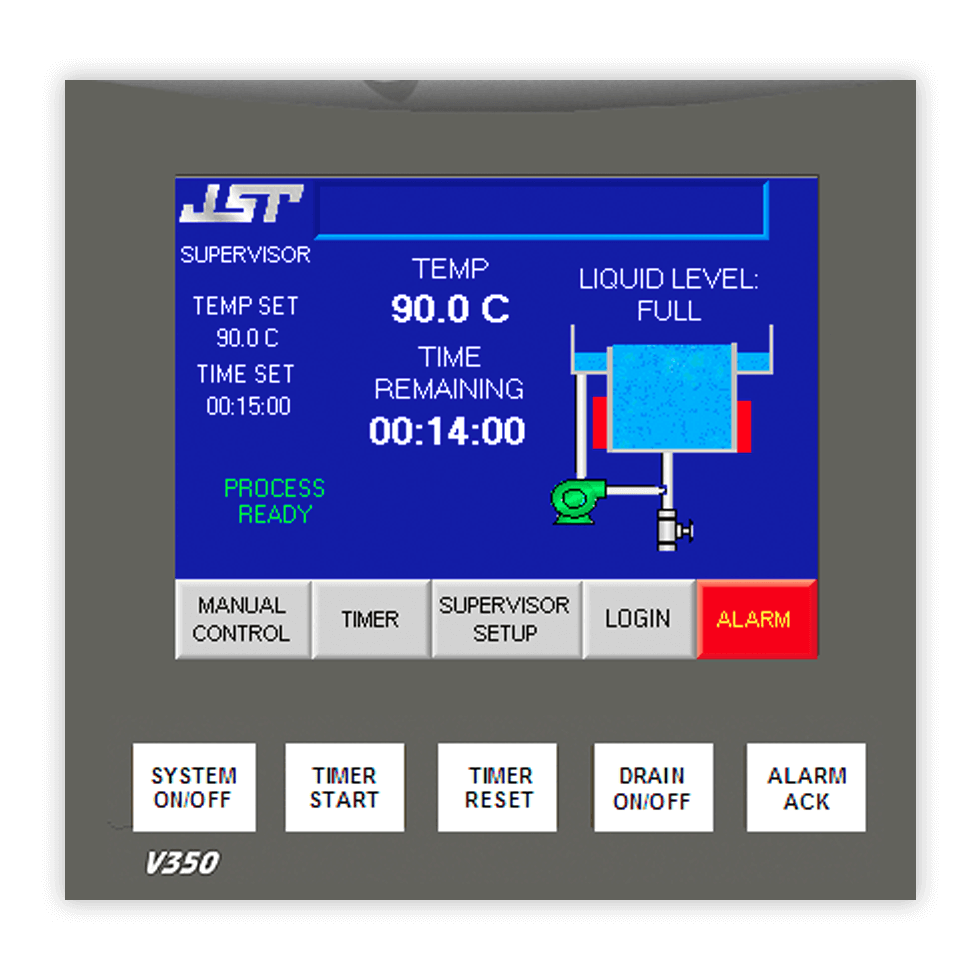

- PLC controlled with color touchscreen

- Programmable temperature and process time

- Full liquid level detection

- Sloped bottom to drain

- Temperature range 40º C- 180º C /- 1.0º

- Thermocouple Type J temperature probe

- Coved corners to eliminate particle traps

- Drain screens

- Air operated valves

- Customizable to fit product

- Ultrasonic agitation

- Megasonic agitation

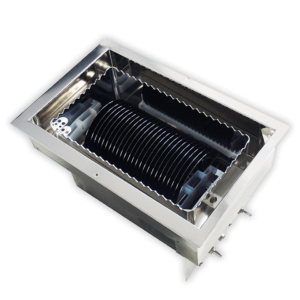

- Condensing cooling coils

- Mechanical agitation

- Automated or manual lid

- Dedicated drain to carboy

- Auto chemical fill and blending

- DIW drip to maintain chemical concentration

- Installation into JST’s Manual Wet Benches or Automated Wet Benches

- Customizable product racks, fixtures, or wafer cassettes

- Resistivity or conductivity monitoring

- Piranha / Sulfuric Peroxide Resist Stripping

- Solvent Photoresist Stripping

- Nitride Etch

- Metal Etch

- KOH Etch / TMAH Silicon Etching

- Mixed acid etch

- SC1 Clean

- SC2 Clean

Heated Static Bath Overview

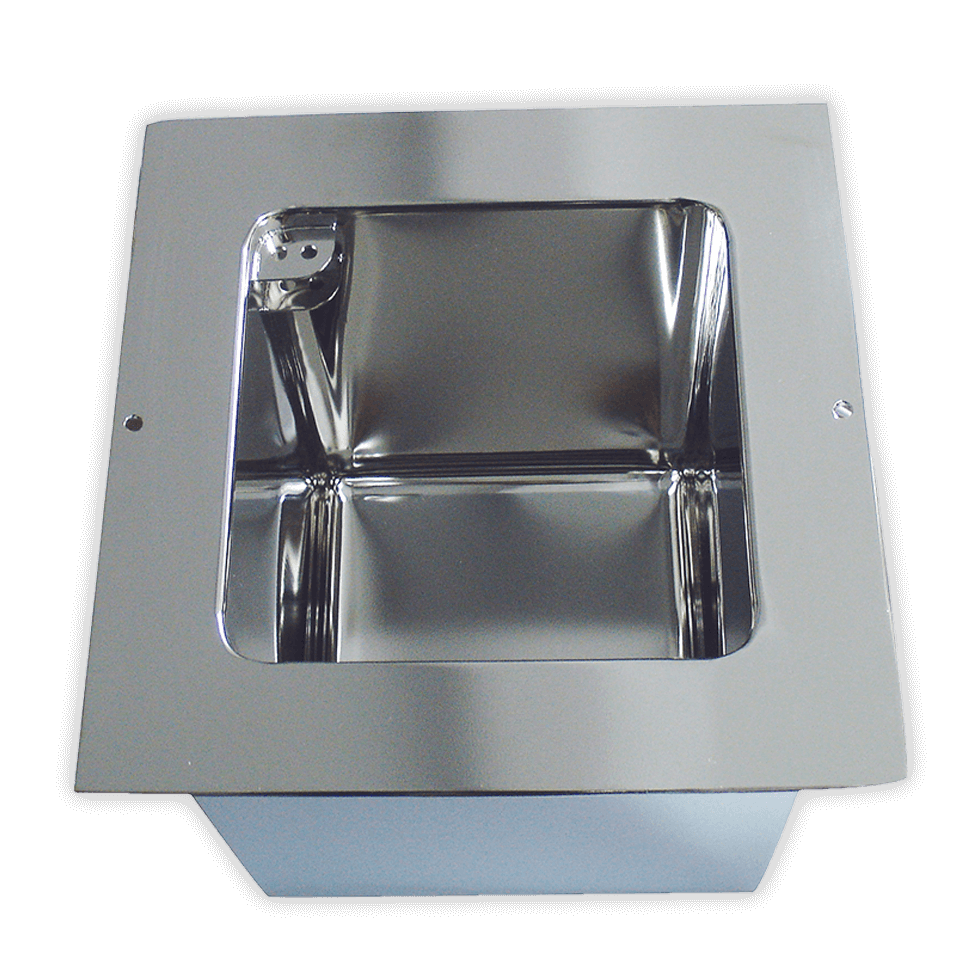

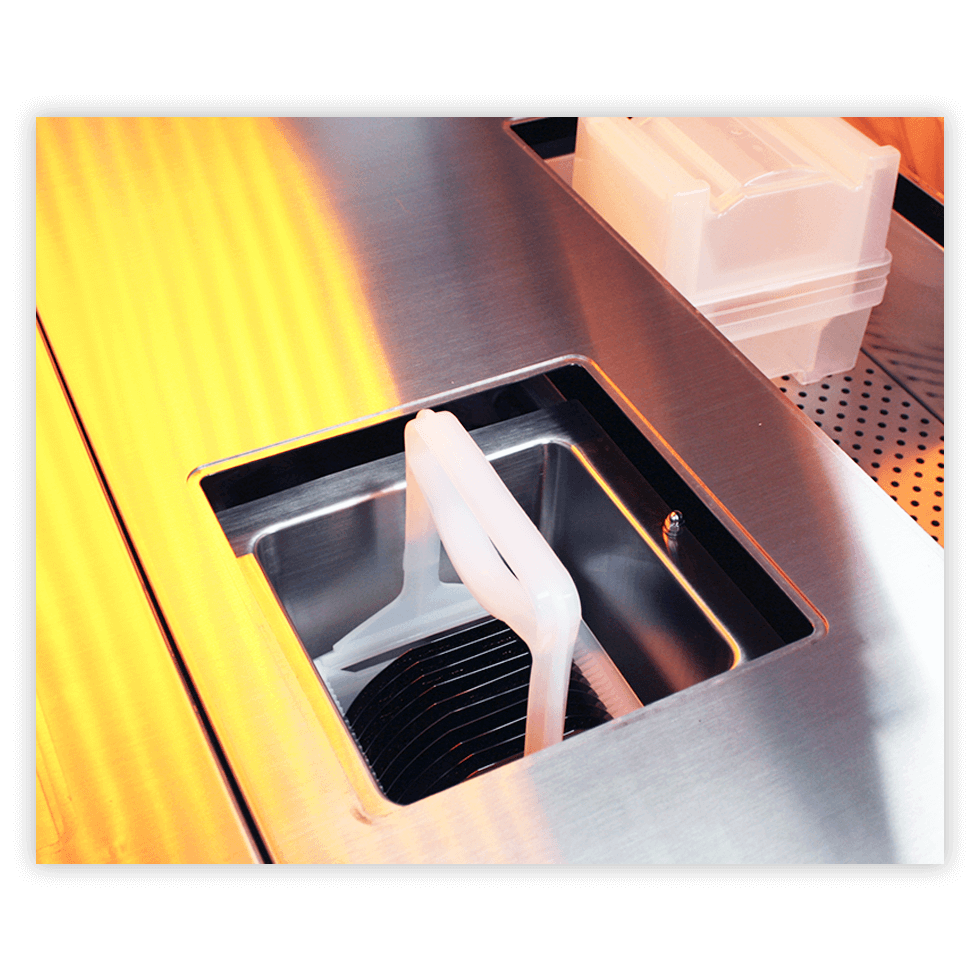

JST offers Heated Static Baths for cleanroom environments that need to maintain uniform temperatures for processing with acids, bases, or solvents. Quartz and stainless steel baths utilize heating elements bonded to the inner walls, which are insulated and enclosed within an N2-purged shroud to control the temperature. The bath is easily customizable to suit the requirements of every cleanroom.

With this product, both temperature and process time is programmable. This bath operates in a temperature range of 40º C- 180º C /- 1.0º with a thermocouple Type-J temperature probe. Plastic baths have submersible Teflon-coated immersion heaters located at the bottom. JST’s Heated Static Baths are designed to safely maintain a consistent temperature for processing acids, bases, or solvents. As with all JST process baths, cove corners, and sloped bottoms provide easy cleaning.

As with all JST products, this bath is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products