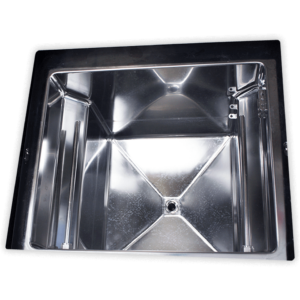

Megasonic Bath

Megasonic Bath

JST’s Megasonic Bath utilizes high-frequency energy (> 700 kHz) to enhance the cleaning performance and effectively eliminate submicron particles through acoustic cavitation.

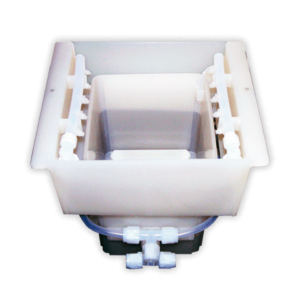

- Material Options: quartz, PVDF, PFA, NPP, or 316L stainless steel

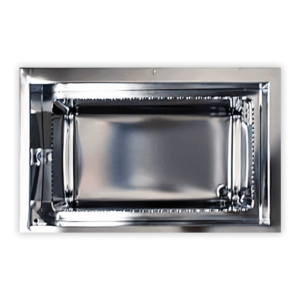

- Indirect megasonic agitation using water boundary layer (quartz material only)

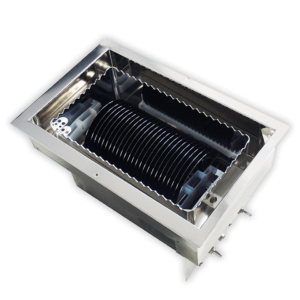

- Direct megasonic agitation using PFA coated or electropolished stainless steel transducer

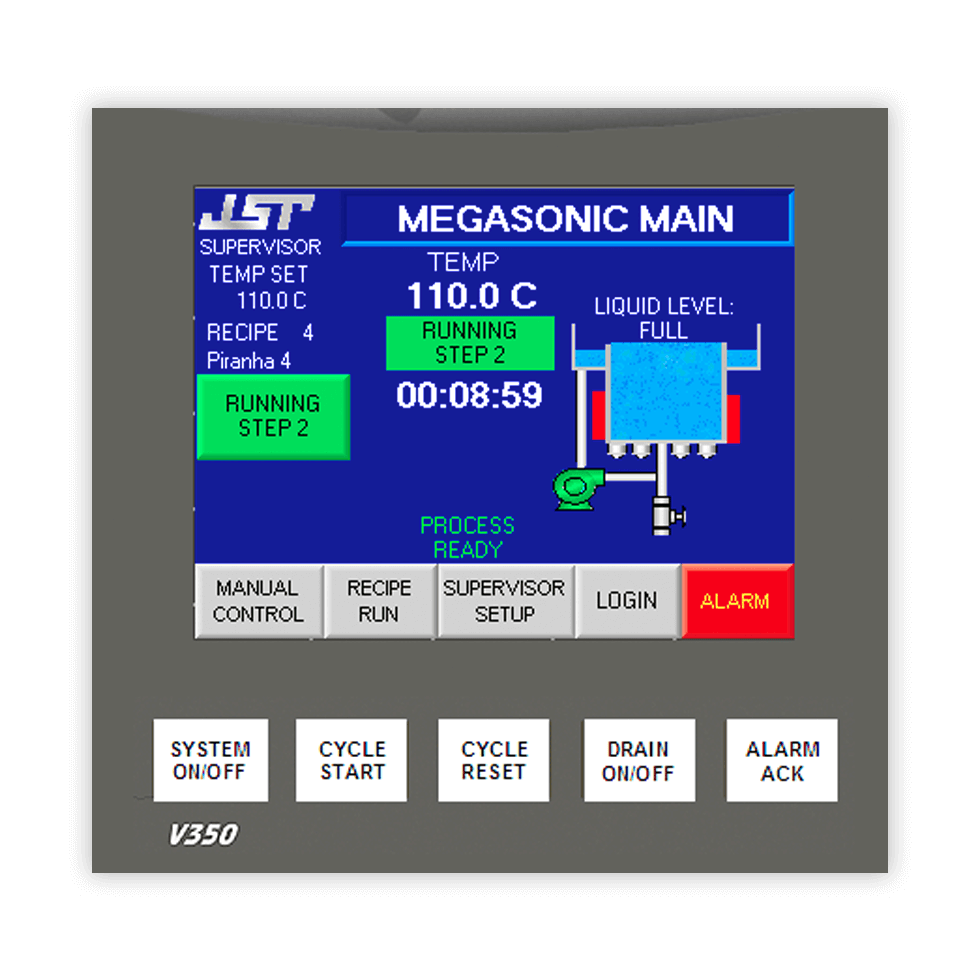

- PLC controlled with color touchscreen

- Programmable power and process time

- Full liquid level detection

- Teflon air operated automatic drain valve

- Coved corners to eliminate particle traps

- Sealed N2 purged transducer enclosure

- Customizable to fit product

- Heating and control systems to maintain +/- 1° C

- 4-sided overflow filtration and recirculation

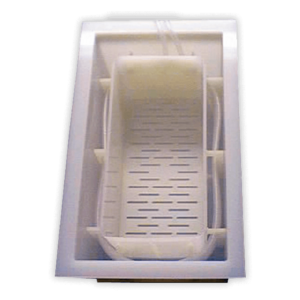

- Customizable product racks, fixtures, or carriers

- Mechanical agitation

- Automated or manual lid

- Solvent, acid, or base processing capability

- Installation into JST’s Manual Wet Benches or Automated Wet Benches

Megasonic Bath Overview

JST’s Megasonic Bath provides a high level of cleaning performance by applying high-frequency energy (greater than 700 kHz) to effectively remove submicron particles via acoustic cavitation. The high-frequency energy and cavitation reduce the boundary layer between the fluid and the part’s surface, resulting in fine particle removal. JST’s baths are designed to provide continuous acoustic energy across the full width and depth, maintaining continuous full coverage.

Elevated temperature can also help lower the chemistry’s surface tension, improving substrate cleaning. JST offers Heated Static Baths, Ambient Static Baths, or Recirculated Megasonic, and Quick Dump Rinsers, allowing customers to fine-tune their processes.

As with all JST process modules, this bath comes with JST’s standard 24/7 Technical Support.

Related Products