Ultrasonic Bath

Ultrasonic Bath

JST’s Ultrasonic Bath is designed to enhance cleaning processes with either solvents or aqueous chemistries. Single and multiple ultrasonic cleaning frequencies are available.

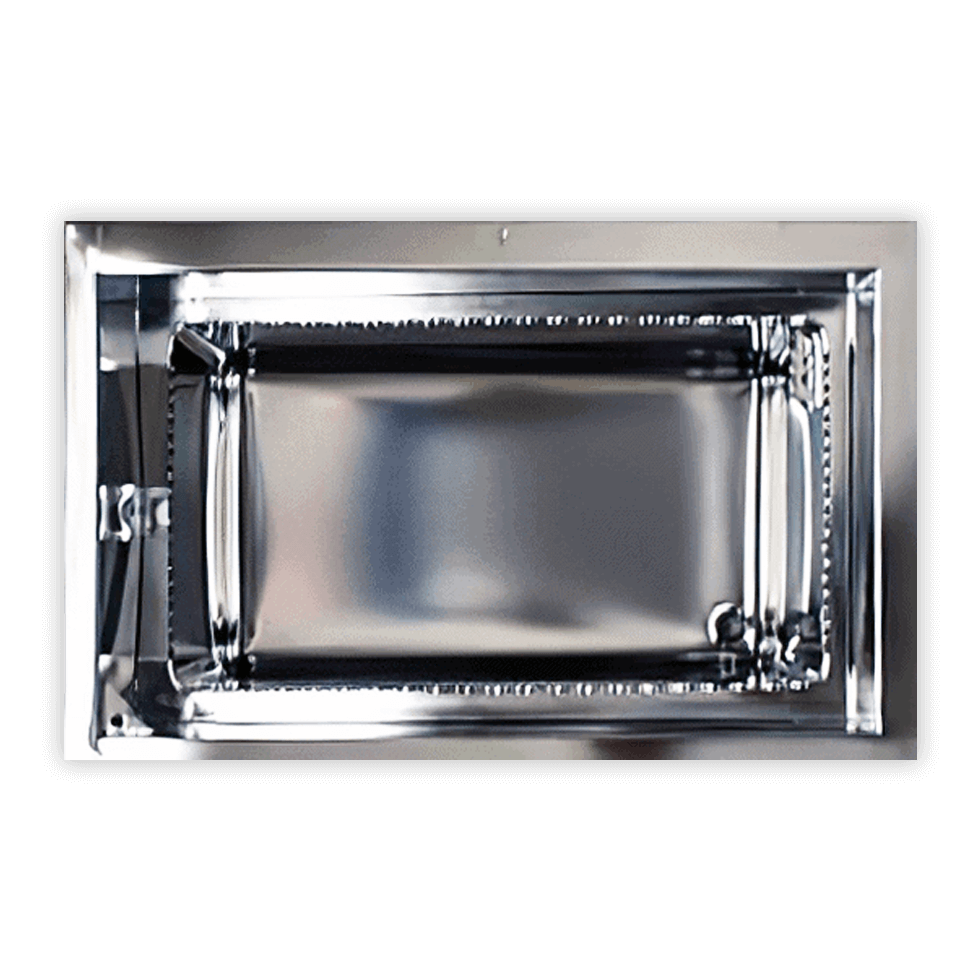

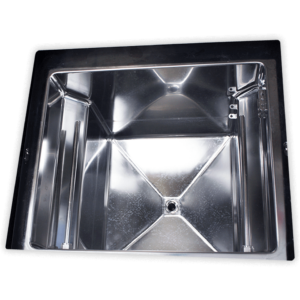

- Material Options: 316L stainless steel, 304L stainless steel, Hastelloy C276, Monel 400, or other alloys are available based on process requirements

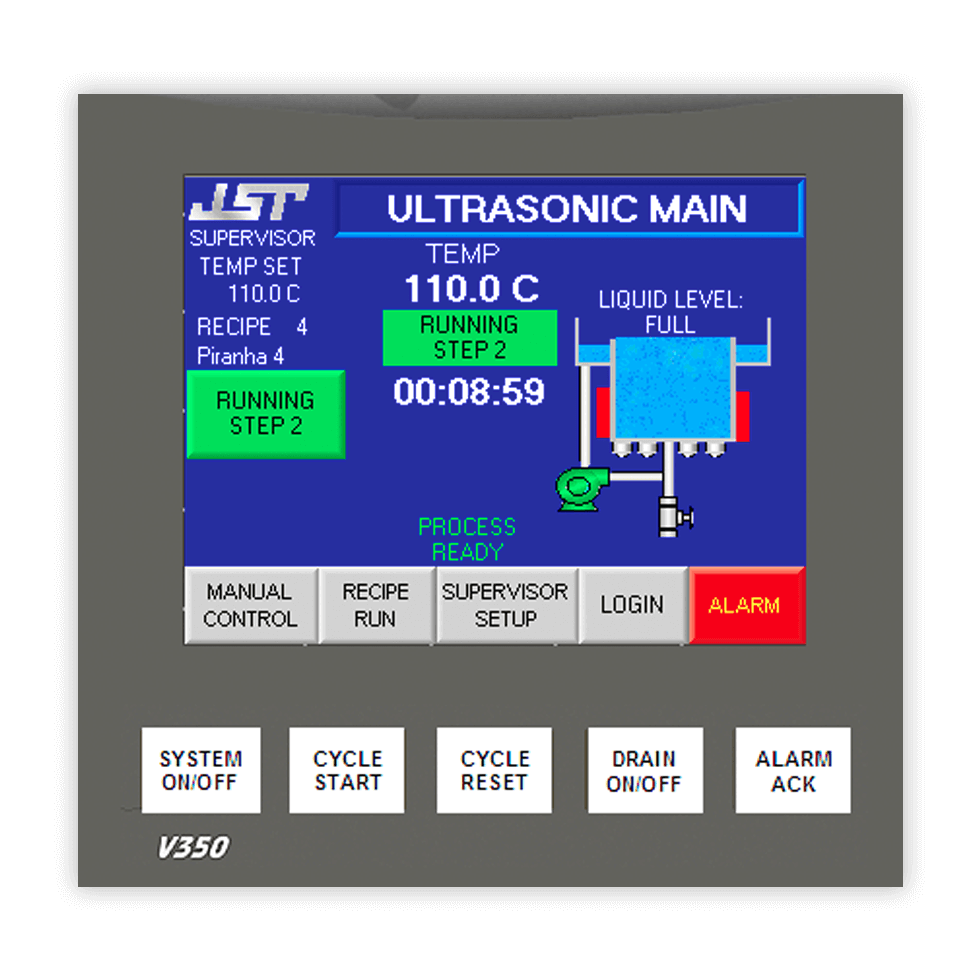

- PLC controlled with color touchscreen

- Programmable ultrasonic power, frequency, and process time

- Full liquid level detection

- Sloped bottom to drain connection

- Teflon air operated automatic drain valve

- Coved corners to eliminate particle traps

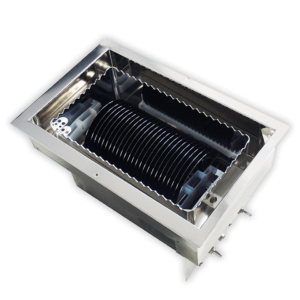

- Single frequencies available: 40, 72, or 104 kHz

- Stainless steel enclosure with N2 purge

- Customizable to fit product

- Multiple frequency baths available: 40, 80, 120, 140, 170, 220, 270 kHz

- Heating and control systems to maintain +/- 1° C

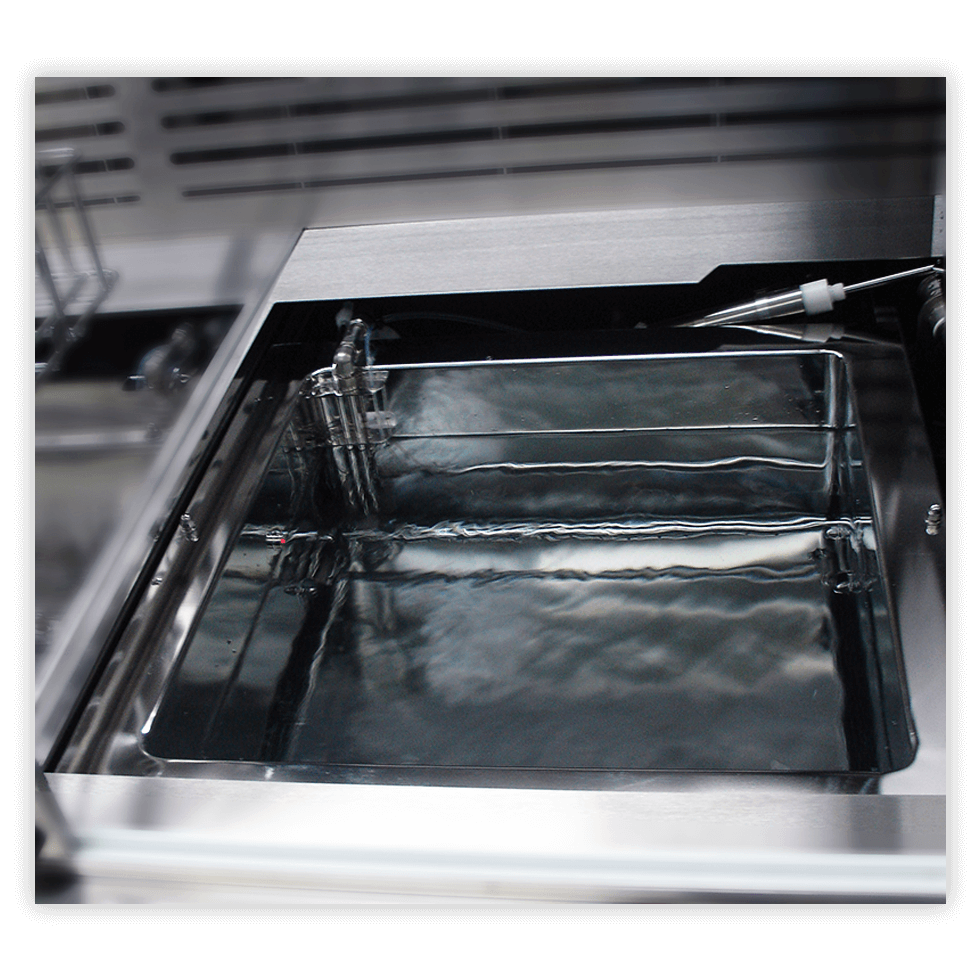

- 4 sided overflow filtration and recirculation

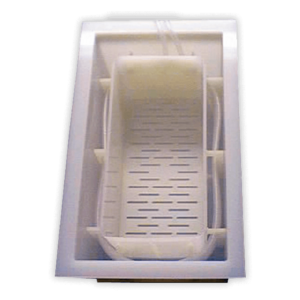

- Customizable product racks, fixtures, or carriers

- Mechanical agitation

- Automated or manual lid

- Electropolish finish

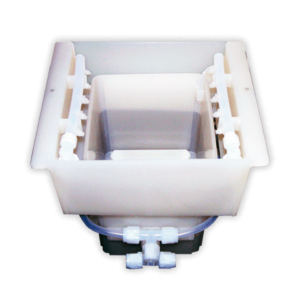

- Acid or base compatible with NPP, PVDF, or PFA bath and immersible alloy transducer

- Installation into JST’s Manual Wet Benches or Automated Wet Benches

Ultrasonic Bath Overview

JST’s Ultrasonic Bath is designed to enhance cleaning processes with either solvents or aqueous chemistries. Single and multiple ultrasonic cleaning frequencies are available.

JST uses only certified, high-performance alloys for maximum strength and long-term durability, making our baths ideal for superior cleaning. This bath is designed to enhance cleaning processes using sound waves with either flammable solvents or aqueous chemistries. Bath designs utilize coved corners to eliminate particle traps, making the bath easy to keep clean. JST’s Ultrasonic Bath cleaner is ideal for critically cleaning semiconductors, optics, disk drive components, flat panel displays, MEMS, and more.

As with all JST process modules, this bath comes with JST’s standard 24/7 Technical Support.

Related Products