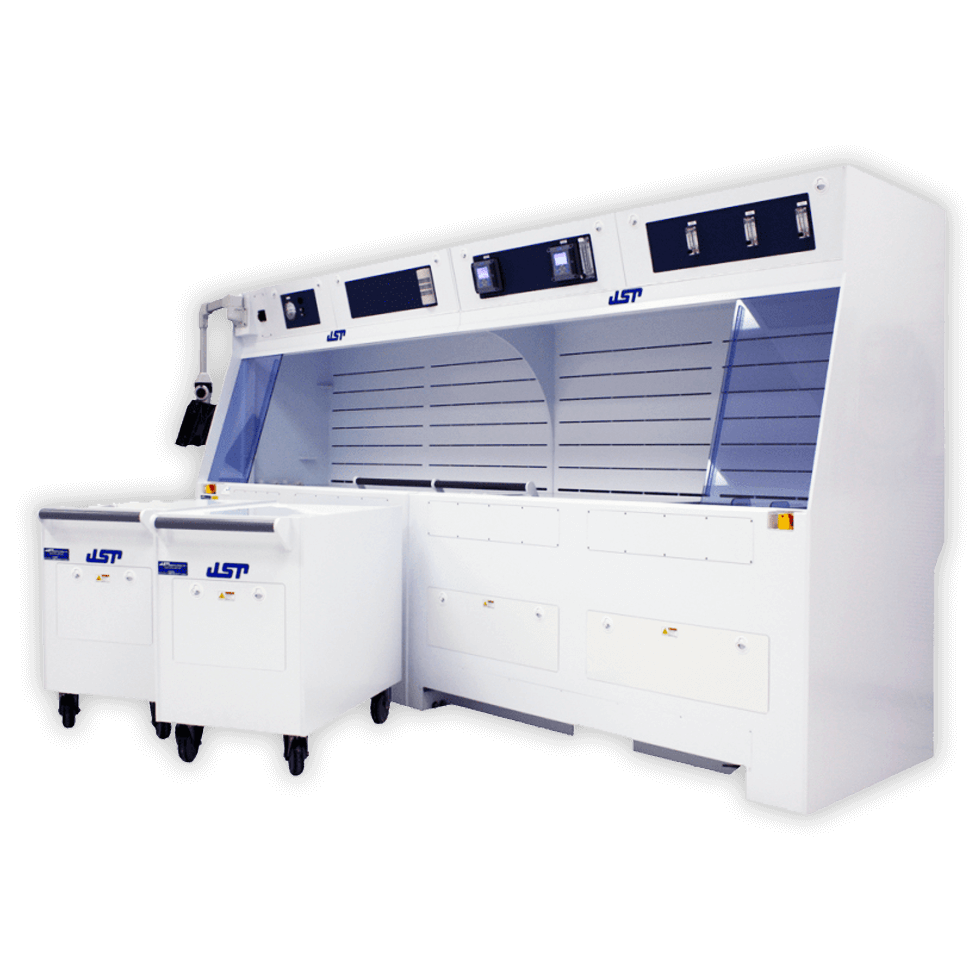

Horizontal Quartz Diffusion Tube Cleaner

Horizontal Quartz Diffusion Tube Cleaner

For cleaning quartz-ware, JST offers a semi-automated, Horizontal Quartz Diffusion Tube Cleaner that uses chemical immersion with parts rotation in an ultra-clean environment.

- Material Options: FM-approved PVC-C or white polypropylene

- Internal stainless steel frames isolated from process chemistry

- Independent tube, paddle, and miscellaneous part processing baths

- Designed with a programmable logic controller (PLC) in addition to a color touchscreen that controls the entire wet bench

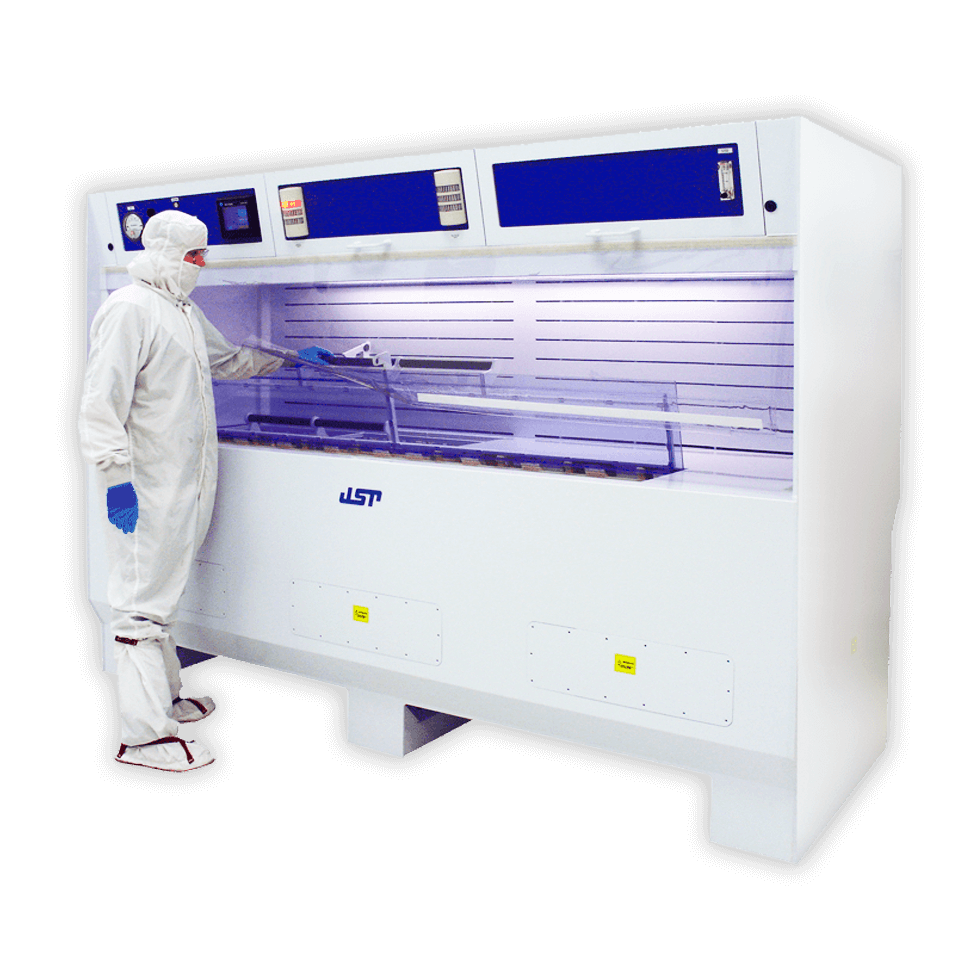

- Ergonomically designed front load/unload access for products

- Semi-automated operation platform

- Front removable panels for easy maintenance access

- Recessed bath design pulls chemical fumes through the exhausted dual containment plenum

- Auto-locking process chamber lids

- Robust variable speed rotational tube drive system for uniform chemical cleaning and reduced chemical usage

- Automated chemical handling using an on-board chemical storage reservoir

- Integrated re-circulation and filtration of process chemistries

- Rear access maintenance area provides dual containment for reservoirs, pumps, filters, and plumbing

- Custom part fixtures

- Additional on-board chemical storage reservoirs

- External Chemical Dispense Cart fill and Chemical Waste Pump Cart

- Bulk chemical fill interface

- On-board chemical analyzer with integrated concentration control and monitoring for reduced chemical usage

- GEM/SECSII factory automation interface

- Ergonomically mounted 23″ color touchscreen monitor with JST’s GENII software

- Local data logging of all process parameters and lot tracking stored on the PC’s hard drive

- Nitrogen and DI water hand spray guns

- Additional facility drain options

- SEMI S2 certification

- CE marking

- 3rd party electrical inspections

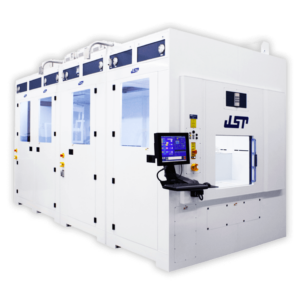

Horizontal Quartz Diffusion Tube Cleaner Overview

JST’s Horizontal Quartz Diffusion Tube Cleaner is designed to restore diffusion-oven quartz tubes, process cassettes, and miscellaneous semiconductor parts to a clean, particle-free state. Each system is designed to meet the customer’s specific needs in terms of process, parts, throughput, size, and chemical usage.

For cleaning quartz ware, JST offers a semi-automated diffusion oven-parts cleaning that uses chemical immersion with parts rotation in an ultra-clean environment. The system rotation of the parts during processing results in uniform cleaning and a reduction of chemical usage. The self-monitoring, ergonomic chemical workstation provides tight process control and technician safety. Other standard features include integrated re-circulation and filtration of process chemistries.

JST customizes all cleaning and etching components at its facility in Meridian, Idaho. The company collaborates with all clients to determine which custom parts fixtures would enhance workflow and throughput. As with all JST wet benches, they are designed for ease of maintenance activities and come with our standard 24/7 Technical Support.

Related Products