KOH Etching

KOH Etching

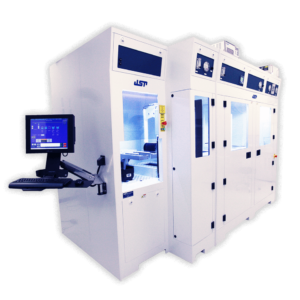

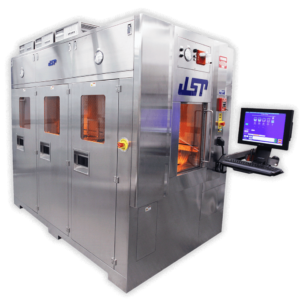

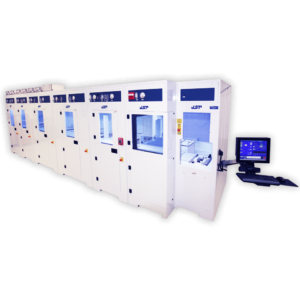

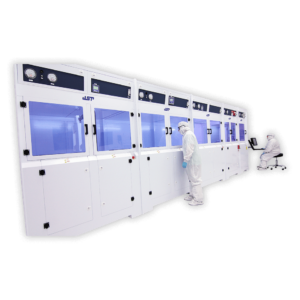

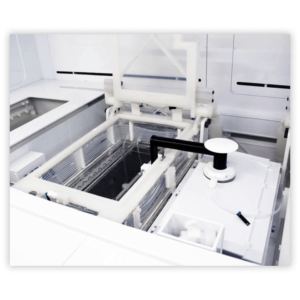

KOH Etching for silicon wafers depends on the concentration of the solution and temperature. JST manufactures manual and automated wet benches that precisely control these two parameters.

- STEP 1: Sulfuric – Quartz Heated Static Bath

- STEP 2: Rinse – Quick Dump Rinser Bath

- STEP 3: KOH – Heated Filtered Bath

- STEP 4: Rinse – Quick Dump Rinser Bath

- STEP 5: Dry – IPA Vapor Dryer

KOH Etching Overview

KOH Etching for silicon wafers depends on the concentration of the KOH solution and temperature. JST can manufacture a manual wet bench or automated wet bench that controls these two parameters with extreme precision. Inline heaters work to control the bath temperature to 0.1°C of the actual set temperature while an onboard ABB unit can actively monitor the concentration of the bath and relay the information to the wet bench PLC. Chemical dosing occurs if the concentration falls below the set point, or DI Water is added if the bath is too concentrated.

JST’s Class 10 Applications Lab enables our customers to develop processes using real-world process tools, modules, and chemicals. This, coupled with our partnerships with various chemical vendors, allows JST to collaborate and develop cleaning solutions for our customers.

All of JST’s wet benches and lab furniture are designed with safety, reliability, and productivity in mind. Our wet processing equipment features a modular design that meets all Semi, CE, NFPA, and OSHA requirements. All cleanroom furniture is designed for safe, convenient, clean, and efficient performance in cleanroom environments Our expertise as semiconductor equipment manufacturers includes onsite plastics and contract metal fabrication as well as mechanical and electrical assembly. As with all JST manual or automated wet benches, the company’s KOH etching process is designed for ease of maintenance activities and comes with standard 24/7 Technical Support.

Related Products