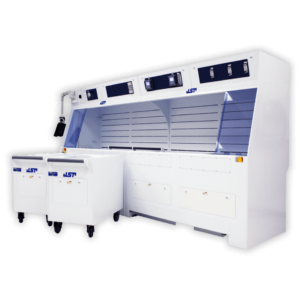

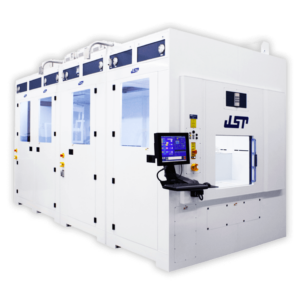

Automated Box Washer

Automated Box Washer

Automated Box Washer dry-to-dry wet bench designed for cleaning wafer cassettes, transport boxes, lead frames, FOUPs, SMIF Pods, or other wafer handling parts.

- Material Options: 304L stainless steel with 316L stainless steel cleaning chamber

- Designed with a programmable logic controller (PLC) in addition to a color touchscreen that control the entire unit

- Exhaust monitor failure alarm

- Rotating top and bottom DIW spray bars

- Static side DIW and N2 spray bars

- Recirculating heated HEPA filtered drying system

- On demand hot DIW heater

- Surfactant reservoir metered dispense

- Purged electrical compartments

- Emergency power off

- Seismic anchors

- Welded sealed secondary containment

- Hinged counterbalanced interlocked door with ergonomic product load/unload

- Integrated recirculation of cleaning chemistry

- Customizable product racks

- Flexible chamber sizing

- ECTFE coated chamber

- Multiple surfactant supply reservoirs

- In-line chemical filtration

- Ergonomically mounted 23″ color touchscreen monitor with JST’s GENII software

- Local data logging of all process parameters and lot tracking stored on the PC’s hard drive

- GEM II / SECS communications

- Additional IR heater to reduce dry time

- SEMI S2 certification

- CE marking

- 3rd party electrical inspections

- Lead Frames

- Process Cassettes

- FOUPs

- FOSB

- SMIF Pods

- Shipping Boxes

- Single Wafer Cassettes

- Lab ware

Automated Box Washer Overview

JST’s Automated Box Washer is a self-contained unit that performs cleaning and drying tasks for sensitive materials, such as substrate-handling cassettes, transport boxes, semiconductor wafers, and disk drive components. Items are placed onto racks and loaded into the washer’s process chamber, where they undergo the Box Washer’s automated cleaning, rinsing, and drying cycle. This automated dry-to-dry wet bench also supports lead frames, FOUPS, SMIF Pods, or other wafer-handling parts.

The washer features rotating top and bottom DIW spray bars and Static side DIW and N2 spray bars. This platform is equipped with a heated, recirculating HEPA-filtered drying system and an on-demand hot DIW heater. To serve the different needs of JST’s customers, customizable product racks and flexible chamber sizes are available for the washer. JST’s washer and dryer box may be customized to include an additional HR Heater for reduced dry time. Other optional features for this platform include multiple surfactant supply reservoirs and in-line chemical filtration, among others.

As with all JST wet benches, the Automated Box Washer is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products