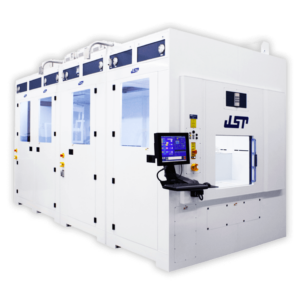

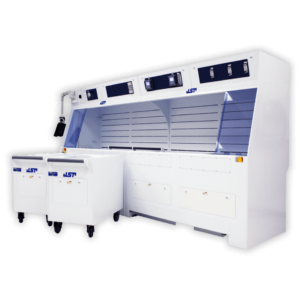

Solvent Photo-Bowl Cleaner

Solvent Photo-Bowl Cleaner

JST’s Solvent Photo-Bowl Cleaner is a specialized fume hood designed for cleaning lithography track system photo-bowls and other miscellaneous parts using solvents.

- Material Options: 304L stainless steel or 316L stainless steel

- Perforated work surface with integrated solvent catch basin below

- Designed with modular programmable logic controllers (PLC) with color touchscreens

- Ergonomically designed front load/unload access for products

- Purged electrical compartments

- Removable work surface

- Exhaust failure alarm

- Emergency power off

- Welded sealed secondary containment

- Seismic anchors

- Clear counterbalance face shield / sash

- Enclosed isolated chemical work and process area

- Low power explosion-proof yellow LED Lighting

- Pressurized solvent spray vessels with point of use hand spray guns

- Bulk fill capable

- Rear access compartment

- Drain to carboy (reusable or disposable)

- HEPA filtration module

- Fire suppression (CO2 or H2O)

- Lower exhausted storage compartment

- External Chemical Dispense Cart fill and Chemical Waste Pump Cart

- Ergonomic control columns

- Hinged or sliding doors

- GFCI outlets

- SEMI S2 Certification

- CE Marking

- 3rd party electrical inspections

Solvent Photo-Bowl Cleaner Overview

JST’s Photo-Bowl Cleaner is a specialized chemical fume hood wet bench designed to provide a safe, exhausted work area for solvent-cleaning of lithography track system photo-bowls. The multiple solvent soak baths, exhausted work surface, and solvent hand sprays provide an ideal workspace to oversee maintenance and cleaning of track system components. It provides a perforated work surface, an integrated solvent catch basin, and an enclosed isolated chemical work and process area.

As a specialized fume hood designed for cleaning lithography track system photo-bowls and other miscellaneous parts using solvents, this product is ergonomically designed with front load/unload product access points for ease of use. The cleaner is designed to safely process and clean parts using flammable solvents in an exhausted, enclosed, and dual-contained area.

As with all JST wet benches, this cleaner is designed for ease of maintenance activities and come with our standard 24/7 Technical Support.

Related Products