Electroless Plating

Electroless Plating

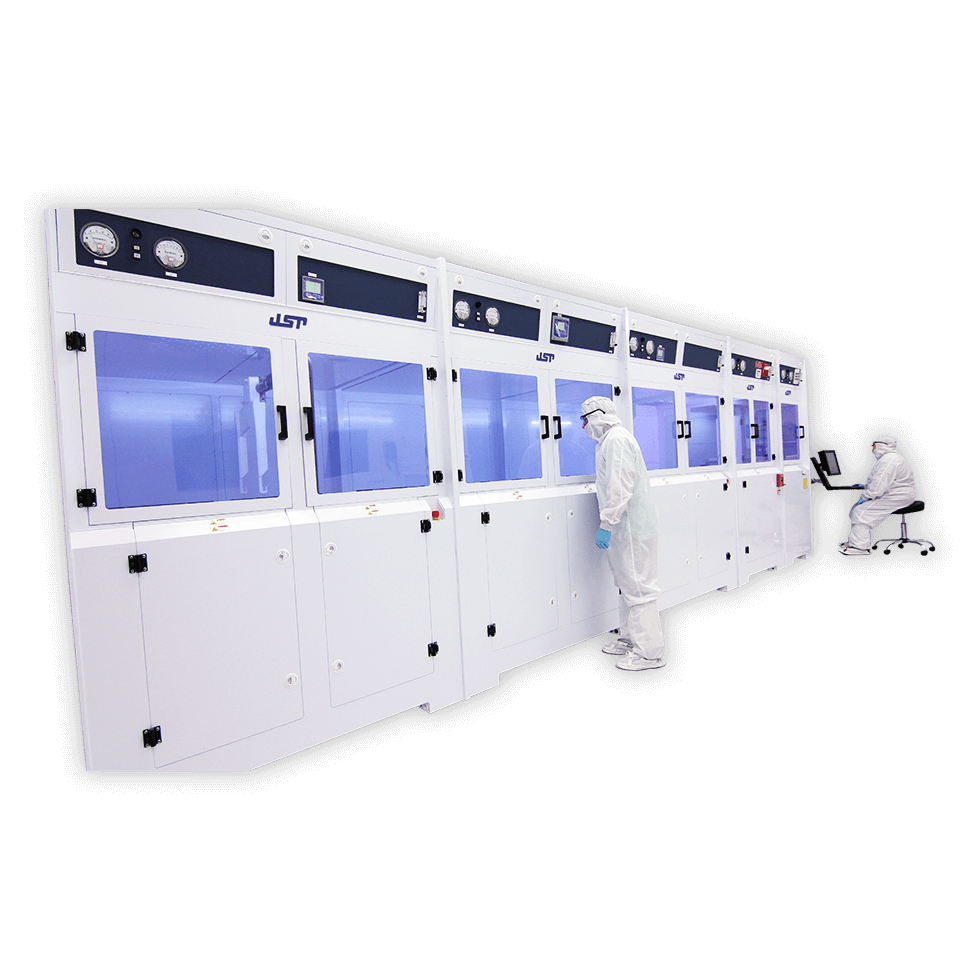

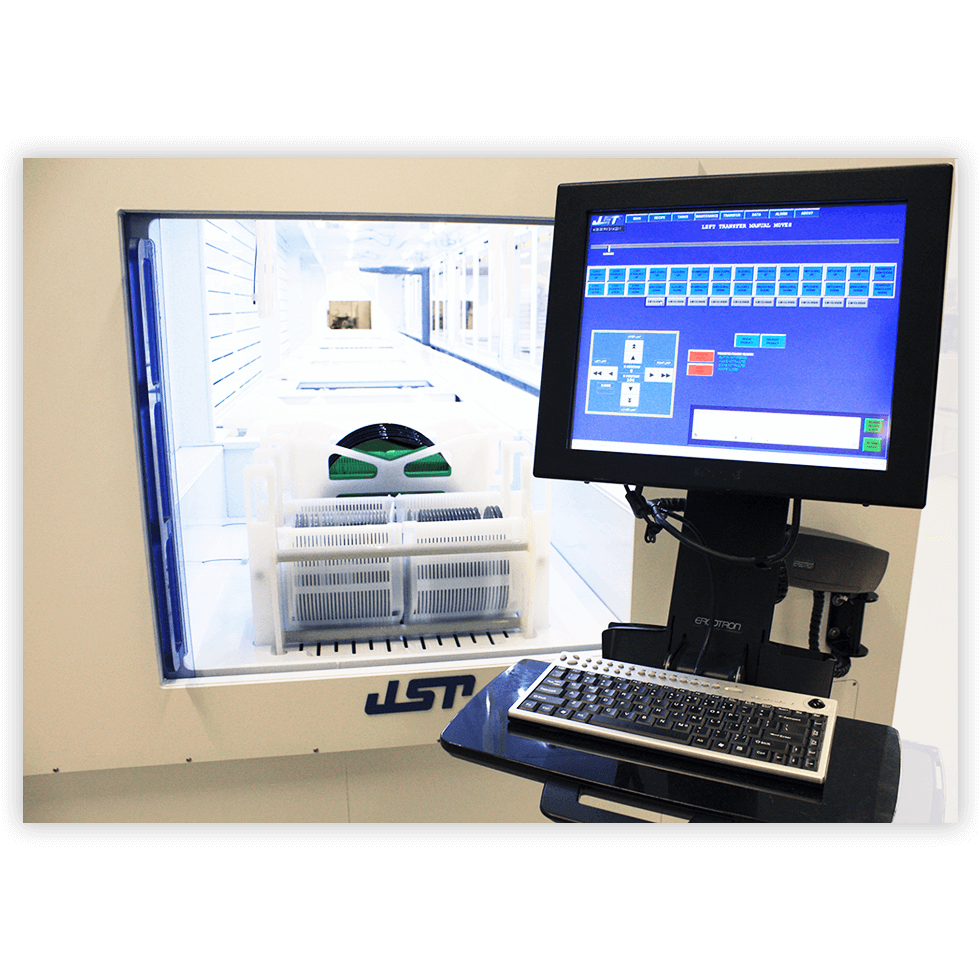

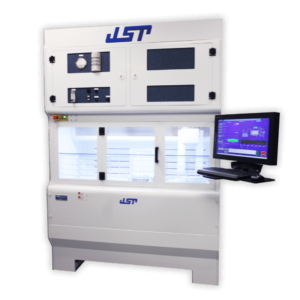

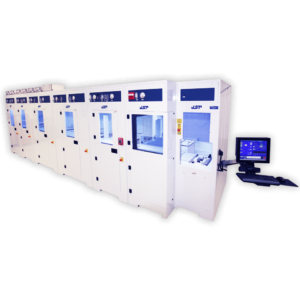

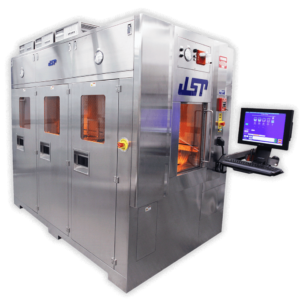

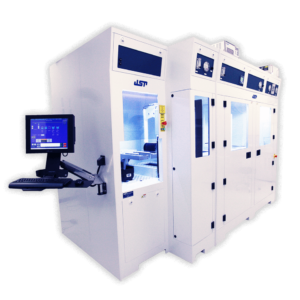

Electroless Plating has a wide variety of applications—from under bump metallization, to plating parts, to help prevent wear and corrosion. JST designs custom manual and fully-automated multi-tasking system wet bench systems.

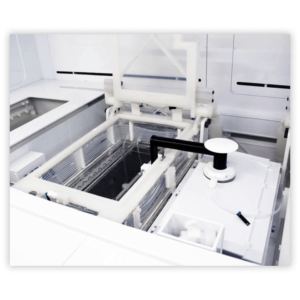

- STEP 1: Acetic Acid Clean Recirculated

- STEP 2: Rinse – Quick Dump Rinser Bath

- STEP 3: Immersion Zincate Heated

- STEP 4: Rinse – Quick Dump Rinser Bath Recirculated Bath

- STEP 5: Electroless Nickel Plating Heated Recirculated Bath

- STEP 6: Rinse – Quick Dump Rinser Bath

- STEP 7: Electroless Palladium Plating Heated Recirculated Bath

- STEP 8: Rinse – Quick Dump Rinser Bath

- STEP 9: Electroless Gold Plating Heated Recirculated Bath

- STEP 10: Rinse – Quick Dump Rinser Bath

- STEP 11: Dry – IPA Dryer

Electroless Plating Overview

Electroless Plating has a wide variety of applications, from under bump metallization to plating parts to help prevent wear and corrosion. Whether you need a simple manual wet bench or a multi-tasking automated wet bench system, JST can design a platform to meet your manufacturing needs.

All of JST’s wet benches are designed with safety, reliability, and productivity in mind. Our wet processing equipment features a modular design that meets all Semi, CE, NFPA, and OSHA requirements. All cleanroom furniture is designed for safe, convenient, and efficient performance in cleanroom environments. The company’s expertise as a semiconductor equipment manufacturer includes onsite plastics and contract metal fabrication as well as mechanical and electrical assembly.

As with all JST manual or automated wet benches, the Electroless Plating process is designed for ease of maintenance activities and comes standard with standard 24/7 Technical Support.

Related Products