Buffered Oxide Etch

Buffered Oxide Etch

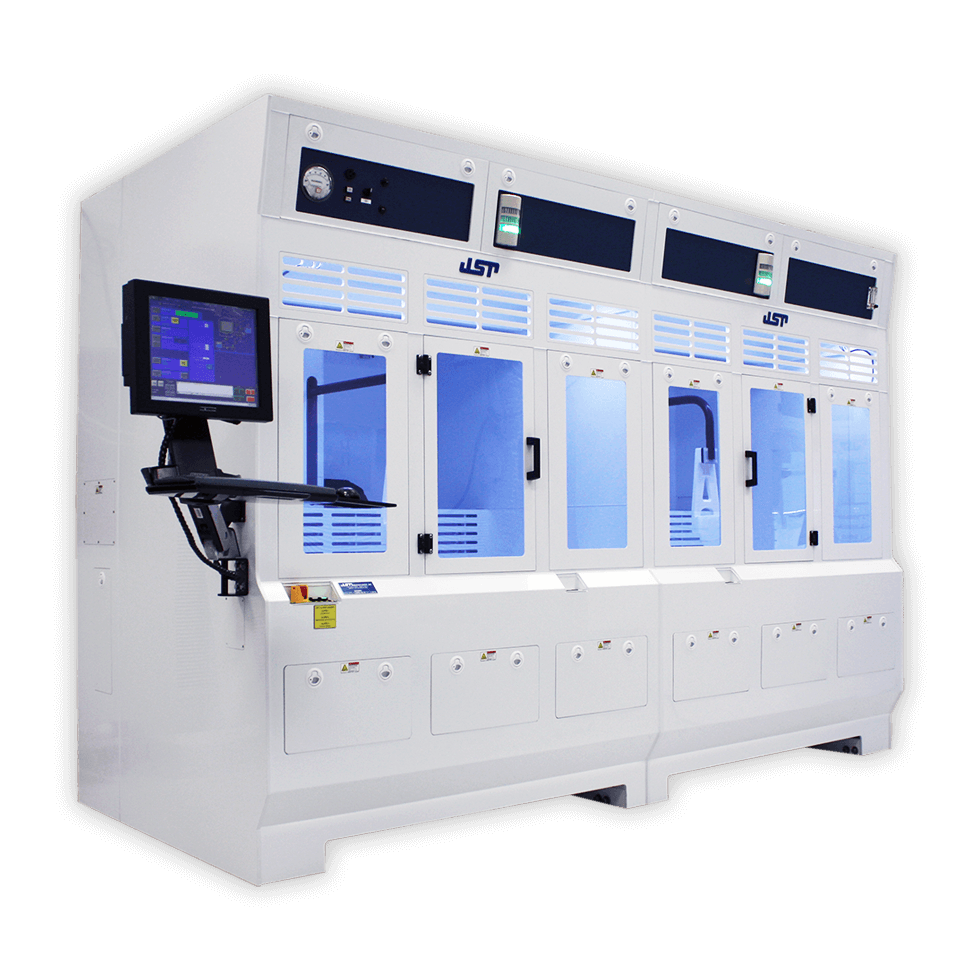

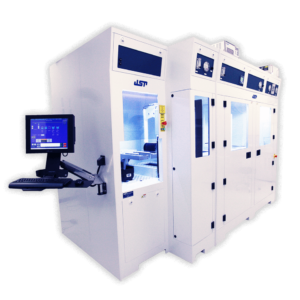

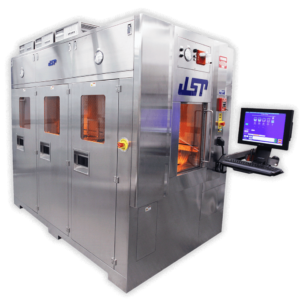

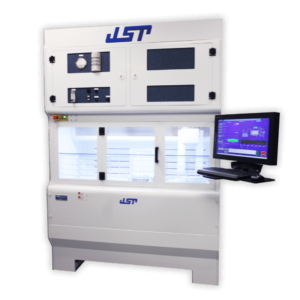

The Buffered Oxide Etch process inscribes thin films of silicon dioxide (SiO2) or silicon nitride off silicon wafers. JST’s wet benches are designed to perform these inscriptions with extreme precision.

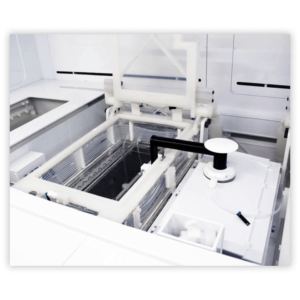

- STEP 1: HF (50:1) – Constant Temperature Bath

- STEP 2: Rinse – Quick Dump Rinser Bath

- STEP 3: BOE – Constant Temperature Bath

- STEP 4: Rinse – Quick Dump Rinser

- STEP 5: Dry – Surface Tension Gradient Dryer (Marangoni Dryer)

Buffered Oxide Etch Overview

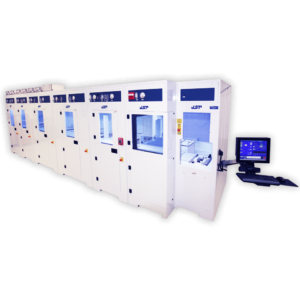

Buffered Oxide Etch is used to etch thin films of silicon dioxide (SiO2) or silicon nitride off silicon wafers. The buffered oxide etch (BOE) process uses a chemical mixed with the HF solution to be reliably controlled for uniform etching across the wafer. Temperature control can be added to the bath, increasing the etch rate, and chemical recirculation to improve the uniformity. JST’s wet benches are designed to perform these etches with extreme precision.

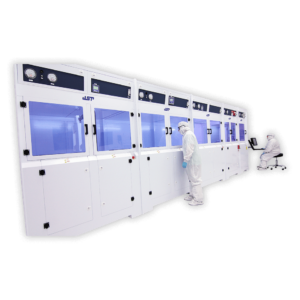

JST has a Class 10 Applications Lab that enables our customers to develop processes using real-world tools, process modules, and chemicals. This, coupled with partnerships with various chemical vendors, allows JST to collaborate and develop cleaning solutions for their customers.

JST’s wet bench equipment and lab furniture are designed with safety, reliability, and productivity in mind. The company’s modular wet processing benches meet all Semi, CE, NFPA, and OSHA requirements. All cleanroom furniture is designed for safe, convenient, clean, and efficient performance in cleanroom environments. As expert semiconductor equipment manufacturers, the company’s capabilities include onsite plastics and contract metal fabrication as well as mechanical and electrical assembly.

As with all JST wet benches, the Buffered Oxide Etch process is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products