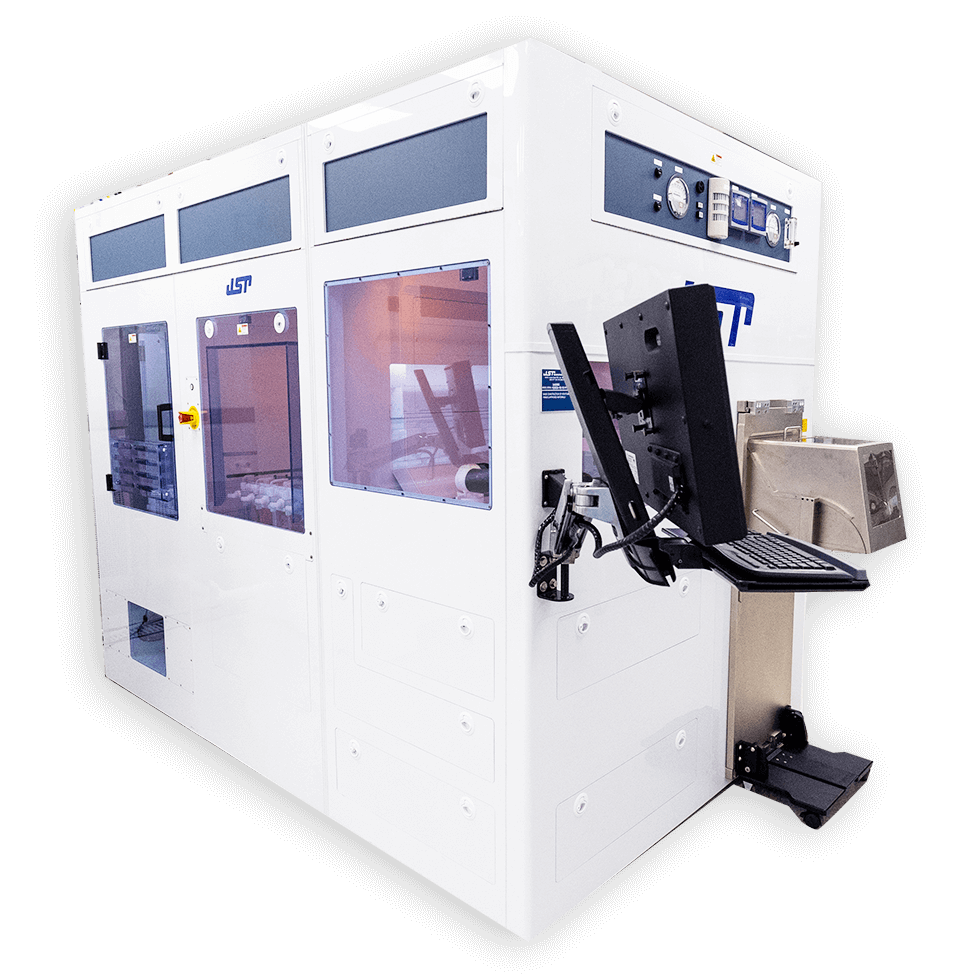

Ospray Single Wafer Wet Process Systems

Ospray Single Wafer Wet Process Systems

JST’s Wet Process Systems apply an automated chemical spray to a single wafer for tight process control.

- Up to 300mm product size capable

- Material Options: 304L stainless steel, 316L stainless steel, FM-approved PVC-C, or white polypropylene with PTFE spray bowl

- Internal stainless-Steel frames isolated from process chemistry

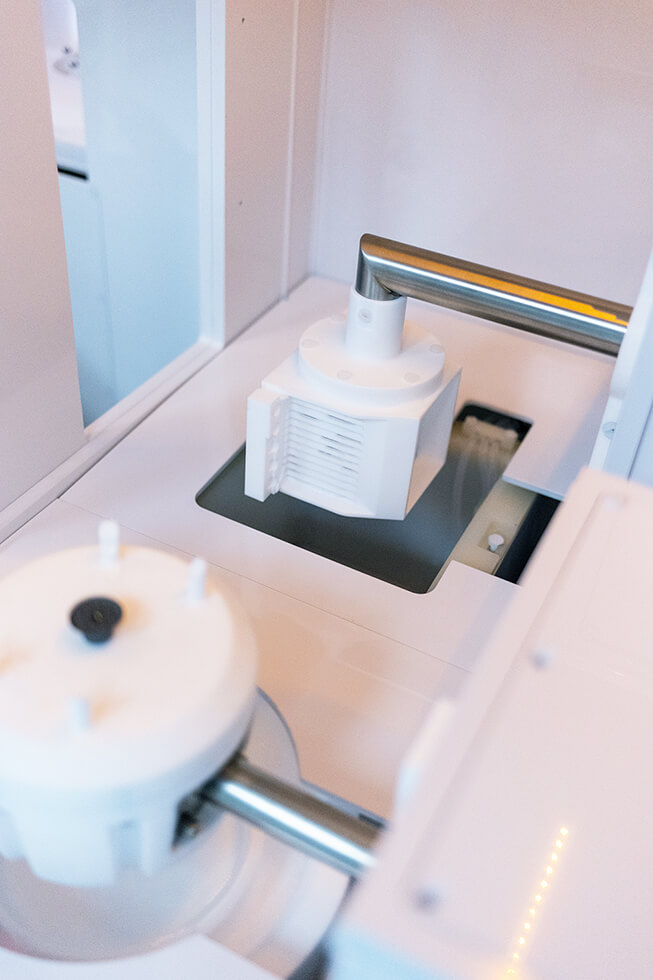

- Automated or manual wafer loading

- Wafer rotation speed control from 1 rpm to 6,000 rpm with a repeatability of .2 rpm

- Active gripping or passive spin chuck available

- DIW backside rinse or backside isolation

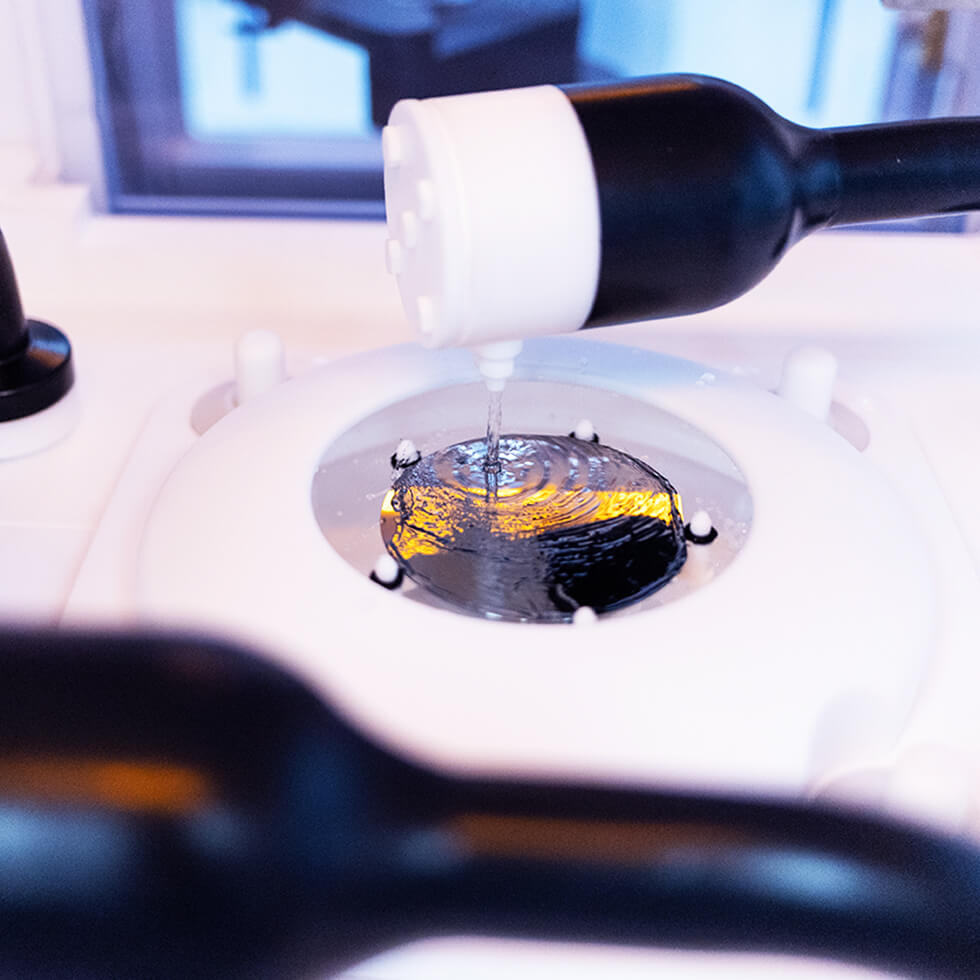

- Programmable servo controlled oscillating spray nozzles

- Programmable chemical flow rate and pressure control

- Precision distance control between nozzles and wafer

- Single pass or chemical recirculation available

- Designed with a programmable logic controller (PLC) in addition to an industrial PC that controls the entire wet bench

- Local data logging of all process parameters and lot tracking stored on the PC’s hard drive

- Ergonomically mounted 23″ color touchscreen monitor, with JST GENII software

- Ergonomically designed front load/unload access for product cassettes

- Multiple spray chambers available for increase throughput

- Rear access maintenance area provides dual containment for reservoirs, pumps, filters, and plumbing

- GEM/SECSII factory automation interface

- CO2 fire suppression system

- Nitrogen and DI water hand spray guns

- On-board chemical analyzer with integrated concentration control and monitoring for reduced chemical usage

- SEMI S2 certification

- CE marking

- 3rd party electrical inspections

- SC1 Clean

- SC2 Clean

- Nitride Etch

- Pre-Gate Clean

- Pre-Metal Clean

- Photoresist Stripping, Post Ash Clean, Post Implant Resist Strip, Post Etch Resist Strip (Optional SC1)

- Metal Lift Off

- KOH Etch

- TMAH Etching

- Aqua Regia Etching

- Silicon Wafer Etching

- Lab or fab material cleaning

- HF, DHF, BOE Oxide Etching

Wet Process Systems Overview

JST’s Wet Process Systems apply an automated chemical spray process to a single wafer for tight process control. This system is equipped with programmable oscillating spray nozzles, wafer speed (RPM), and precision adjustment of the distance between the nozzles and the surface of the wafer. JST’s Wet Process Systems provide process engineers with unprecedented flexibility, precision, and repeatability during the etching and deposition process.

Automated dispensing from the chemical storage reservoir provides repeatable control of volume and mixing. Chemical flow rate and pressure are controlled and programmable. The active gripping or passive spin chucks are designed for DIW backside rinsing or backside isolation. JST’s single-wafer wet process system is compatible with any JST chemical or rinses process modules.

JST’s Single Wafer Wet Process system performs Nitride Etch, KOH Etch, TMAH, Aqua Regia, Silicon, HF/DHF/BOE Oxide Etching, Metal Liftoff, SC1, SC2, Pre-Diffusion Clean, Pre-Gate Clean, and Pre-Metal Clean tasks. JST’s single wafer processing equipment can be configured for either automated or manual wafer loading. Control over wafer rotation speed falls between 1 rpm and 6,000 rpm with repeatability of .2 rpm. This system is customized to user specifications, and offered with a choice of auto or manual wafer loading/unloading configurations.

This wet bench may also be modified to include Photoresist Stripping, Post-Ash Clean, and Post-Implant Resist Strip processes. As with all JST wet benches, single-wafer wet process tools are designed for ease of maintenance activities and come with our standard 24/7 Technical Support.