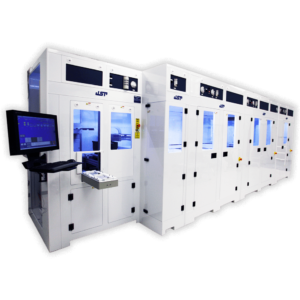

Tigress XL Automated Wet Bench

Tigress XL Automated Wet Bench

JST offers the Tigress XL Automated Wet Bench as an alternative for customers seeking a low-cost, adaptable compact chemical wet bench platform.

- Up to 200mm product size processing capable

- Material Options: 304L stainless steel, 316L stainless steel, FM-approved PVC-C, or white polypropylene

- Internal stainless steel frames isolated from process chemistry

- Industry-leading compact footprint

- Designed with a programmable logic controller (PLC) in addition to an industrial PC that controls the entire wet bench

- Local data logging of all process parameters and lot tracking stored on the PC’s hard drive

- Ergonomically mounted 23″ color touchscreen monitor, with JST GENII software

- Ergonomically designed front load/unload access for product cassettes

- Automated, multi-tasking, or semi-automated operation platforms

- Compact dual-axis linear transfer provides stable high-speed product movement

- Front access maintenance with easy lift-off front roll panel

- Recessed bath design pulls chemical fumes through the exhausted dual containment plenum

- Compatible with any JST chemical or rinse process modules

- More than three modules available based on product size (150mm or smaller)

- Rear access maintenance area provides dual containment for reservoirs, pumps, filters, and plumbing

- GEM/SECSII factory automation interface

- CO2 fire suppression system

- Nitrogen and DI water hand spray guns

- On-board chemical analyzer with integrated concentration control and monitoring for reduced chemical usage

- Dry to Dry configuration using JST’s IPA Dryers

- Active Gripping End Effector for carrier-less processing

- SEMI S2 certification

- CE marking

- 3rd party electrical inspections

- SC1 Clean

- SC2 Clean

- Nitride Etch

- Pre-Gate Clean

- Pre-Metal Clean

- Photoresist Stripping, Post Ash Clean, Post Implant Resist Strip, Post Etch Resist Strip (Optional SC1)

- Metal Lift Off

- KOH Etch

- TMAH Etching

- Aqua Regia Etching

- Silicon Wafer Etching

- Lab or fab material cleaning

- HF, DHF, BOE Oxide Etching

Tigress XL Automated Wet Bench Overview

JST offers the Tigress XL Automated Wet Bench as an alternative for customers seeking a low-cost, adaptable compact chemical wet bench platform. This unique compact wet bench requires a minimum of floor space and a lower exhaust requirement while generating higher throughput. The Tigress XL compact dual-axis linear transfer provides consistent, high-speed product movement and particle-free results. This system is ideal for wet chemical processing tasks requiring three process modules and high throughput.

This three-bath footprint system processes products up to 200mm in size. Compatible with any JST chemical or rinse process modules. The Tigress XL also supports Dry to Dry processing using JST’s Marangoni or STG Combo Rinse Dryer as an additional option.

The Tigress XL wet bench is configured with look-ahead scheduling software, a feature that allows process technicians to process multiple lots with unique recipes at the same time. This multitasking capability saves time and floor space while maintaining repeatability and throughput. JST’s Tigress XL can be configured to include an on-board chemical analyzer with integrated concentration control, which monitors and reduces chemical usage. The Tigress XL can also be configured to accommodate more than its standard three modules, based on a product size of 150mm or smaller.

As with all JST wet benches, the Tigress XL is designed for ease of maintenance activities and comes with our standard 24/7 Technical Support.

Related Products